1. Introduction

2. Materials and Methods

2.1 Materials

2.2 Methods

3. Result and Discussion

4. Conclusions

1. Introduction

It is well known fact that the binder in hot-mix asphalt (HMA) mixture is aged during short-term aging (STA) period at high temperature while haul-and-queue in truck before paving. If the HMA is produced using a polymer-modified asphalt (PMA) binder, a higher temperature will have to be used to maintain quality compaction due to the higher stiffness of binder. If the temperature is higher and the time is longer than normal, the binder is becoming further aged in an exponential function form (Kim et al., 2016). When the mix is aged, the binder of mix becomes stiffer. However, it is not well known how much aging is induced in this short-term aging period due to the elevated temperature and extended time. Although several studies examined significance of aging in normal asphalt binder mixes, few study examined aging of PMA mixes (Han et al., 2015). Especially when the anti-strip additive (ASA) is added to the mix for stripping control, the aging level will be varying depending on the function of additive used because the ASA reacts as a chemical component in oxidation reaction at high temperature.

According to recent studies (Kim et al., 2019; Ahn et al., 2015), if the normal HMA mixes were subjected to short-term aging for two hours (2-h) at 180°C, the absolute viscosity (AV) was increased to the AV level of recovered binder from the core of several year-old surface course in Korean highways. If this aged mix is paved in the field, the service life of the pavement will be reduced by several years because it has been aged already that much level before paving. Therefore, controlling aging level during short-term aging period is important for future pavement life.

There are two types of ASAs available in the market; the hydrated lime (HL) and liquid additive (LA). The HL, which has been widely used in the world, is well known for retarding age-hardening of normal asphalt (without polymer) in HMA. However, the HL reaction as an antioxidant in polymer-modified asphalt (PAM) is not much evaluated. Many brands of LAs have also been developed for stripping protection purpose. However, their chemical reaction for age-retardation in HMA is not also known because the heat-stability in asphalt mix is not clearly informed from the producer.

Therefore, for oxidation level evaluation, the stiffness of binder in the mixes with different ASA was examined in this study. The large-molecular size (LMS) measured from the dissolution of mix has been known to have a very high correlation with viscosities, high-temperature stiffness (G*/sin δ) and DSR (dynamic shear rheometer) critical temperature of asphalt (Ahn et al., 2015; Han et al., 2015; Jennings, 1985; Jeong et al., 2017; Kim et al., 2019; Kim et al., 2004). Therefore, this study measured the LMS of each binder from the dissolution of mix in two hours for three replicate of one mix without binder recovery, which requires cumbersome and significant time consuming lab works.

The objective of this study was to evaluate age-retardation effect of different ASAs on the stiffness (G*/sin δ) of asphalt binder in the mixes, which were subjected to short-term aging at 180 and 185°C. The estimated G*/sin δ from the LMS obtained by the gel-permeation chromatography (GPC) test was used for age-retardation effect comparison. This study results can be utilized for selection of ASA type in the mix, once the comparison of oxidation levels disclosed if the LAs showed identical age-retardation effects to HL.

2. Materials and Methods

2.1 Materials

The polymer-modified asphalt (PMA: PG76-22) binders were prepared using a low-density polyethylene (LDPE) and a styrene-butadiene-styrene (SBS) for the stone mastic asphalt (SMA) mixes. A normal PG64-22 asphalt binder was also used in preparation of a dense-graded asphalt (DGA) mix for comparison purpose. Granite coarse aggregates with a nominal maximum aggregate size of 10 mm (for SMA) and 13 mm (for DGA) were used with the granite screenings as fine aggregate and a lime stone powder as mineral filler. A hydrated lime (HL) and two liquid additives (LAx and LAy) were used as anti-strip additives. The LAx and LAy were pre-mixed additives, which were applied into the PMA when manufactured by the producer. The content of ASA and application method is shown in Table 1.

Table 1. Description of Materials and Methods Used in This Study

2.2 Methods

The mixture used in short-term aging was prepared using the optimum asphalt content (OAC) which was determined based on the Korean mix design guide (The Ministry of Land, Infrastructure and Transport, 2015). Nearly a half of asphalt mixes are paved during early winter time every year in Korea. The normal temperature of DGA mixes at this time of the year was measured to be 180°C which is at least 20°C higher than the normal HMA temperature on average (Lee et al., 2014). The DGA mix prepared at OAC was therefore short-term aged at 180°C and the SMA mix at optimum PMA content was short-term aged at 185°C, which was suggested to be average temperature of SMA in truck by the Korea Expressway Corps (Korea Asphalt Society, 2017).

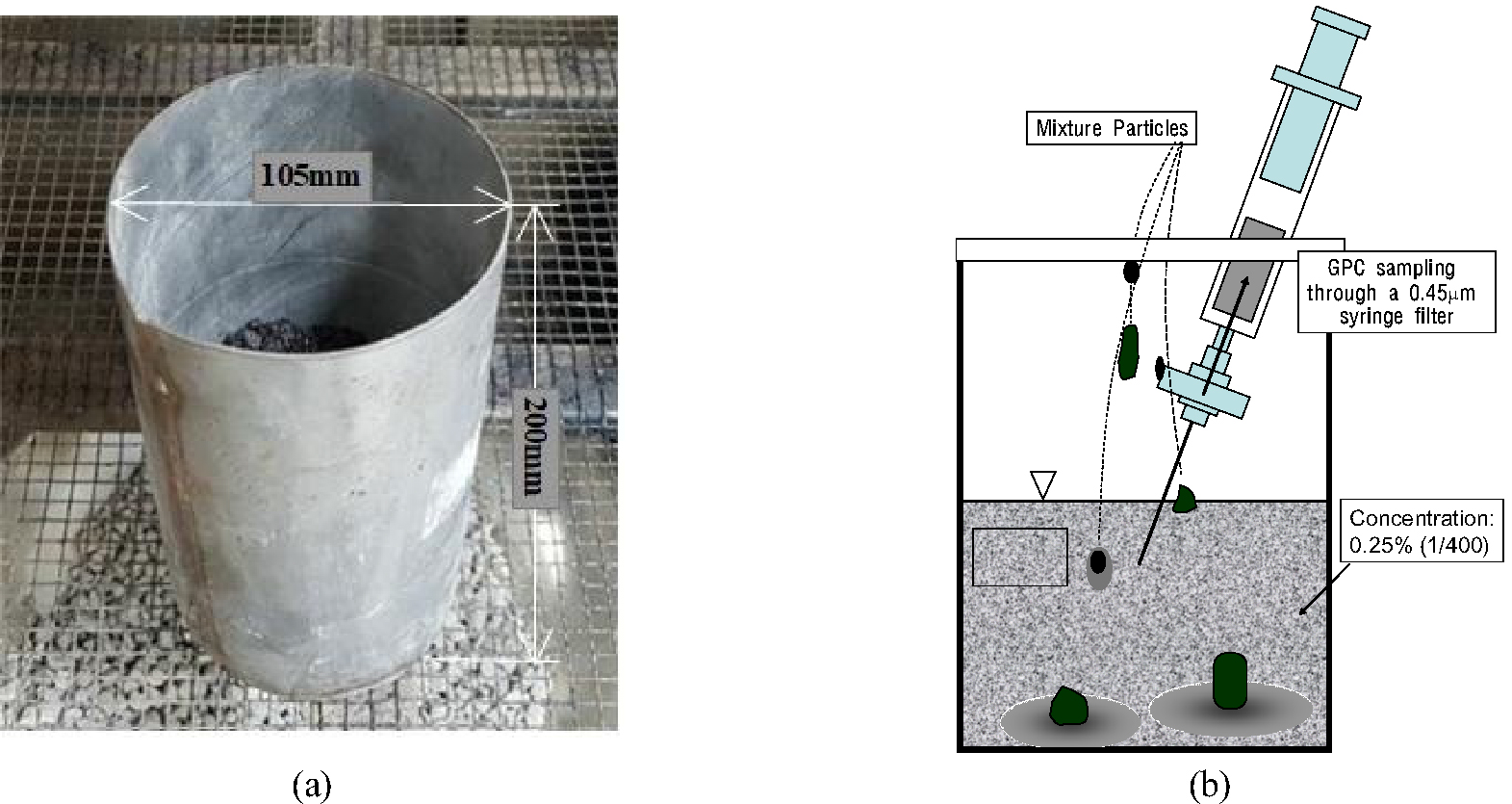

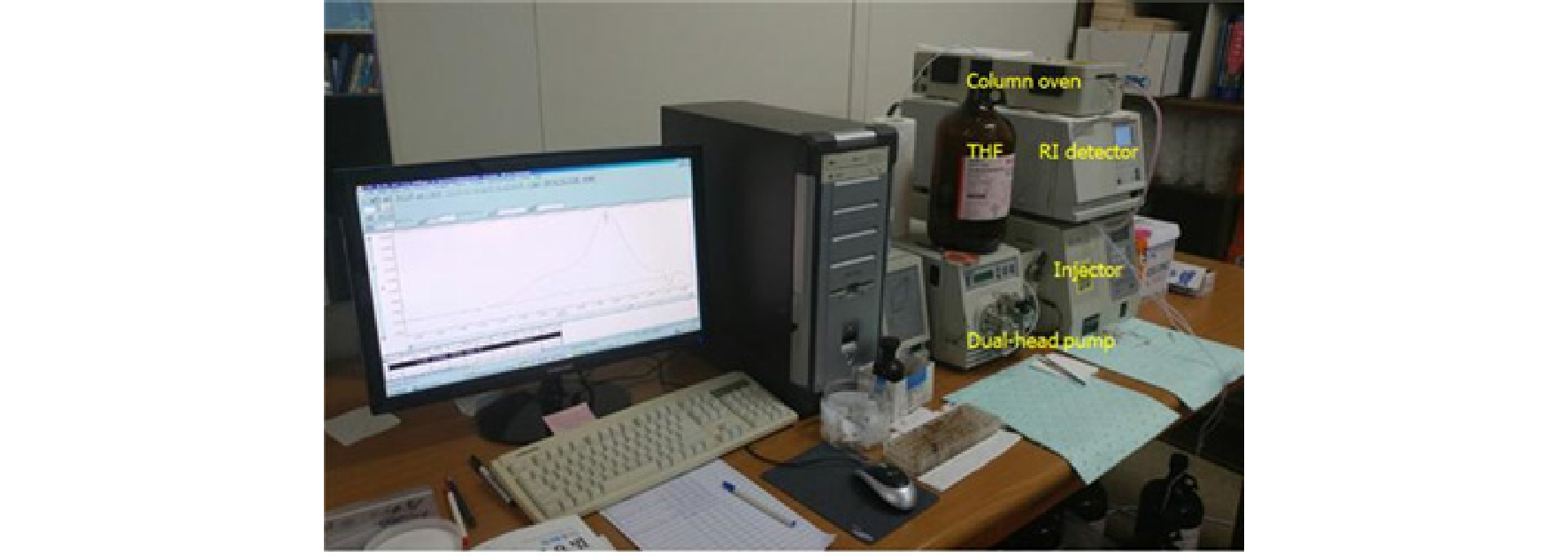

The loose mixture blended by a paddle mixer was short-term aged in a canister (Fig. 1(a)) which is placed in a drying oven without forced air draft. Since haul- and-queue of mix can take several hours in a worst case scenario due to severe traffic jams and operation problem in metropolitan area job sites, the three short-term aging times were investigated. One hour (1-h) was considered the optimistic time, 2-h the most likely time, and 4-h the pessimistic (poorest) time for short-term aging (Kim et al., 2016). The asphalt mix sample was dissolved into tetra-hydro-furan (THF; a strong solvent) for GPC test, as shown in Fig. 1(b). The sample concentration was adjusted to be 0.25% by weight based on asphalt content of the mix. The GPC sample solution was extracted from the dissolution using a syringe through a mounted 0.45 μm syringe filter. A 50㎕ of the sample was then injected into the GPC injector (Fig. 2).

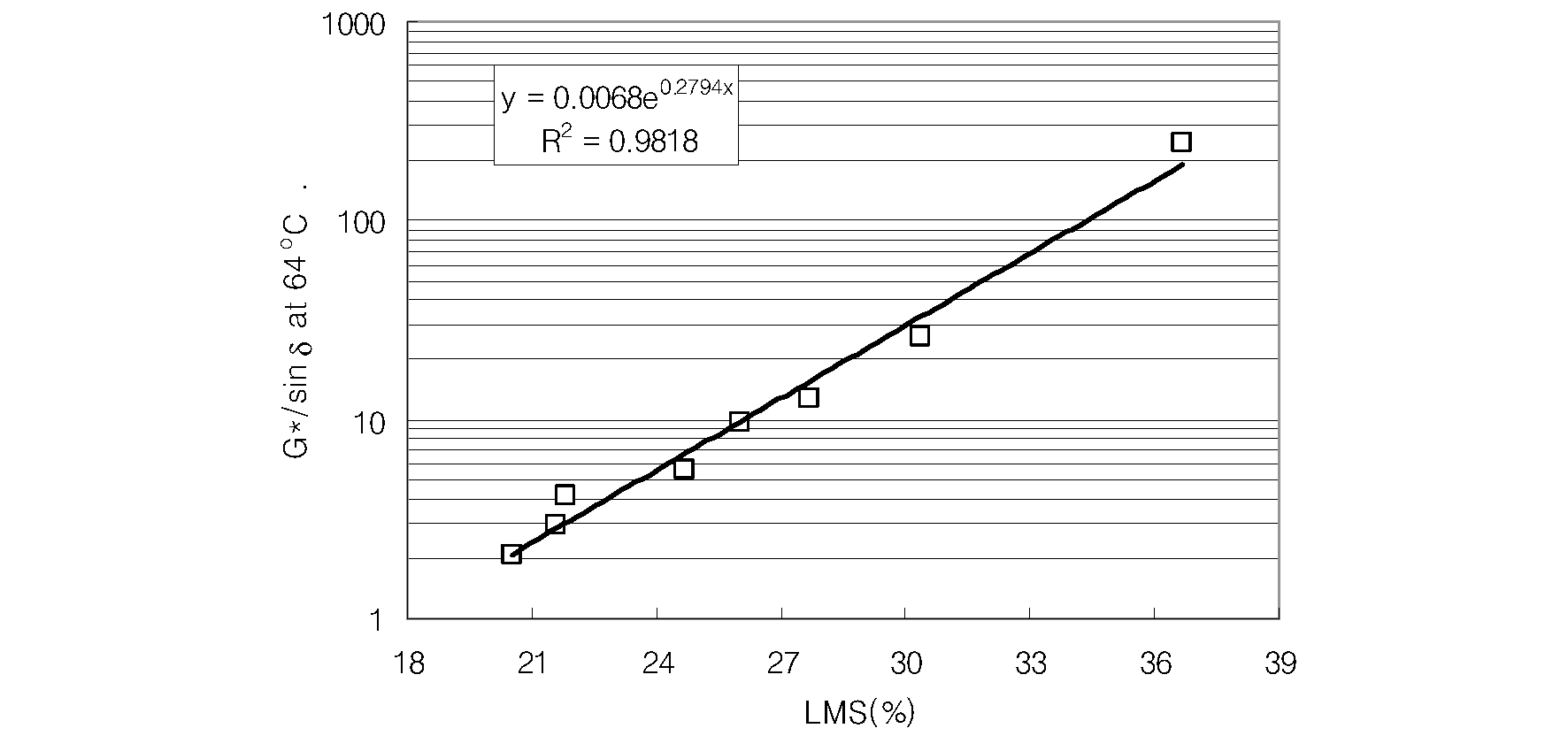

All samples were used for GPC test without recovery to measure LMS values. According to previous study (Kim et al., 2019), G*/sin δ showed excellent correlation (R2 > 0.98) with LMS values as shown in Fig. 3. Therefore, the best-fit regression model (y=0.0068e0.2794x) was used to estimate G*/sin δ from LMS.

3. Result and Discussion

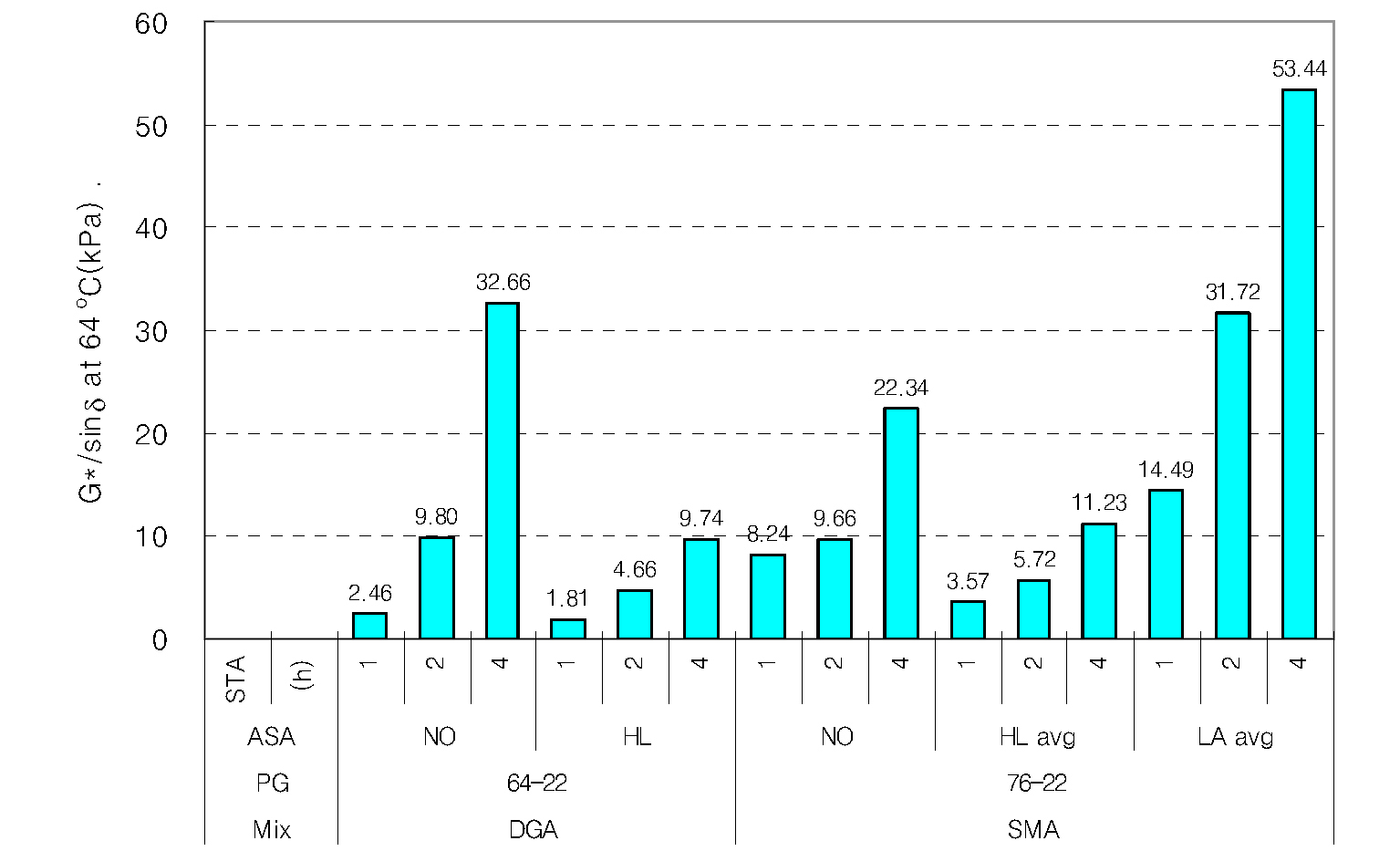

Table 2 shows measured LMS and estimated G*/sin δ values for each short-term aging time. The G*/sin δ values were estimated from the LMS based on the regression models in Fig. 3. In the regression model (y=0.0068e0.2794x) in Fig. 3, the y, G*/sin δ at 64°C,was computed by replacing x with LMS. The G*/sin δ values were used for further aging analyses throughout the study.

Table 2. Measured Absolute Viscosity (MAV), LMS and Estimated Absolute Viscosity (EAV)

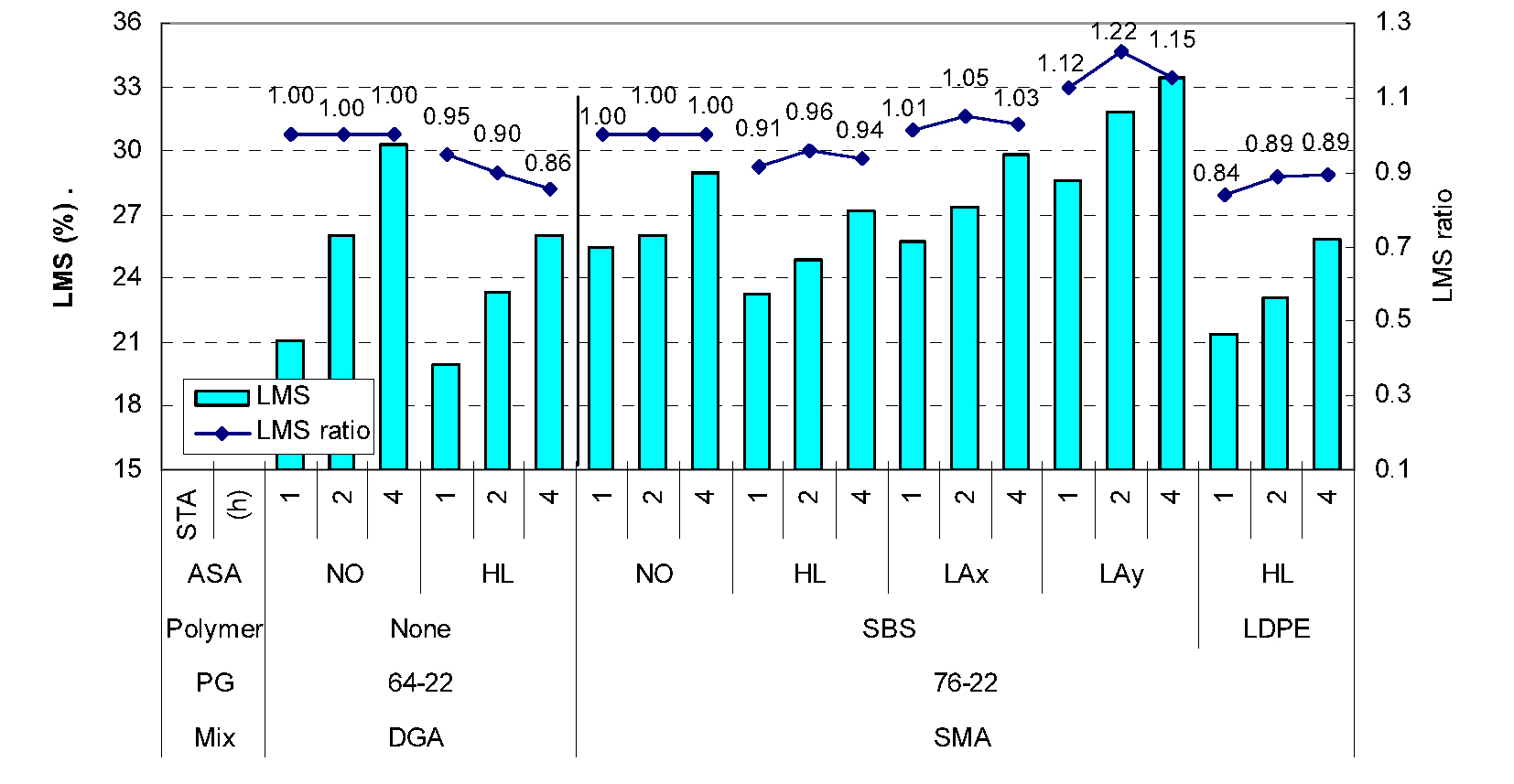

Fig. 4 shows LMS values and LMS ratios, which were computed for each short-term aging (STA) time based on the LMS of ASA NO for 64-22 and 76-22 binders, respectively. All of LMS values increased by short-term aging time increase from 1-h to 4-h. This is an indication that the binder age-hardening is increased by the short-term aging time increase for all binders, showing LMS levels of PMA are higher than those of normal asphalt.

In normal binder (PG 64-22; polymer None), use of HL showed lower (reduced) LMS values than the binder without (NO) ASA in all 3 short-term aging times, showing the ratio decreasing pattern by STA time increase. In PMA binder (PG 76-22; SBS and LDEP), LMS values of PMAs with HL were lower than those of NO, indicating effectiveness of HL on age-retardation of PMA binder in all three STA times. The LMS ratios of both polymers with HL were below 1.0, with LDPE showing lower ratios than SBS. However, both LAs showed higher LMS values than NO, revealing all LMS ratios being over 1.0. While LAx showed slightly higher LMS level to those of NO, LAy showed much higher LMS values than NO in all three short-term aging time. From LMS comparison, it was evident that liquid additives had no effective age-retardation function in PMA binders.

Since LMS is not a familiar to most engineers, the G*/sin δ was utilized as an index for the aging comparison. Since the binder recovery is a troublesome process, in stead of measuring G*/sin δ from recovered binder, it was estimated from LMS for all mixture samples without recovery. The estimated G*/sin δ values by ASA group mean are shown in Fig. 5 for PMA binder for visual comparison. The significance of aging difference was more evident by estimated G*/sin δ values as the stiffness has relation to LMS in exponential function.

In normal binder (64-22), G*/sin δ values of HL in 3 short-term aging times were reduced significantly from those of NO ASA. In PMA binder (76-22), the average G*/sin δ value of HL were also significantly lower than those of NO. Therefore, it was evident that HL was effective on retarding aging hardening of normal binder and PMA binders too. Although LAx showed identical stiffness values to those of NO as shown in Table 2, the average values of LA were much higher than those of NO in all 3 STA times in Fig. 5, because stiffness of LAy was significantly higher in all 3 STA times. Therefore, it seems that liquid additives do not have age-retardation function in PMA binders. By looking G*/sin δ level of LAy, it brings up a query about chemical components that might include some catalytic substance(s) making age-hardening acceleration.

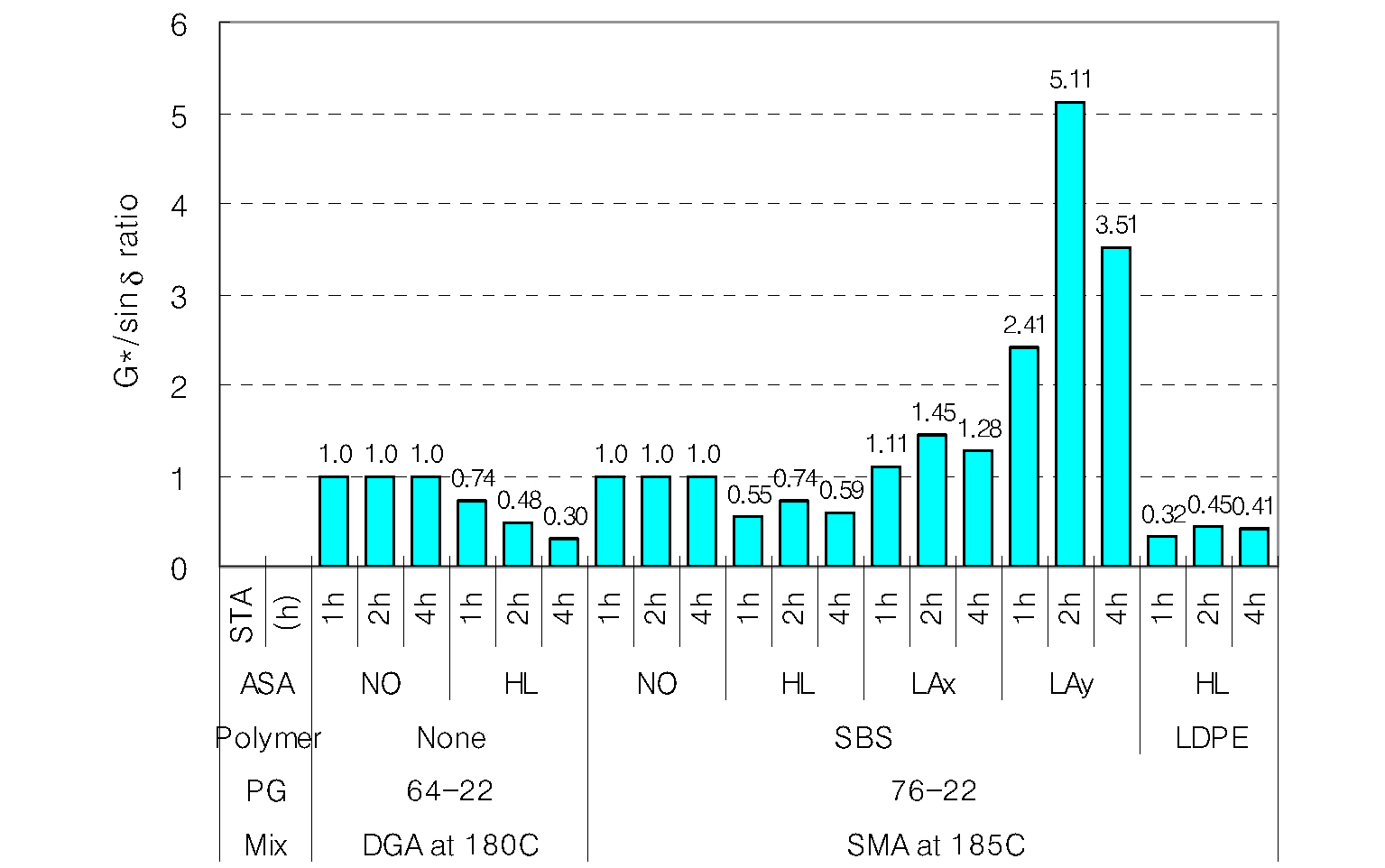

For comparison of stiffness by each short-term aging time for normal and PMA binders, stiffness ratios were computed based on the stiffness value of ASA NO for 64-22 and 76-22 binders, respectively. Fig. 6 shows that stiffness ratio of 1.0 in all three short-term aging of ASA NO in both binders. From this type of figure, effectiveness of ASA as an age-retarder can be compared by the factored number.

In normal binder (64-22), since the ratio of HL was decreased by short-term aging time increase, the age-retardation effect of HL was found to be increased by short-term aging time increase. From this finding, it can be presumed that the HL effect for retarding age-hardening becomes greater in increasingly severe aging conditions. In SBS PMA binder, stiffness ratios of HL were maintained under 0.74 (average being 0.63), and in LDPE PMA, the number were below 0.45 (average being 0.39) in all short-term aging times. According to this finding, it was obvious that the HL effect for age retardation was similar in PMA binders, compared with normal binder. The most effectiveness for age retardation of HL was achieved in LDPE PMA.

However, stiffness ratios of LAx were higher than those of NO, showing 1.45 and 1.28 in 2-h and in 4-h short-term aging, respectively. The LAy showed extremely higher ratios than any other ASAs in all three short-term aging time. Therefore, as already mentioned earlier analysis, it seems that both liquid additives do not have any age-retardation function. Instead, the LAy might have some other material(s) included for expediting aging of asphalt under hot temperature. Since the aging level due to short-term aging is irreversible in pavement layers once the mixture is paved, the long-term aging starts further aging from the aging level where the short-term aging was terminated. Therefore, if a severe aging like LAy is not properly controlled during short-term aging stage, the later field performance of asphalt pavement will be significantly affected thereby.

4. Conclusions

This study evaluated the age-retardation effect of anti-strip additive (ASA) in polymer-modified asphalt (PMA) binders (PG76-22) in SMA mixes, which were short-term aging (STA) conditioned for 1 hour (1-h), 2-h and 4-h at 185°C in a drying oven. A normal asphalt (PG64-22) was also evaluated for comparison purpose. The hydrated lime (HL) and two liquid additives (LAx and LAy) were used to control stripping, but this study evaluated only the age-retardation effect of those additives in PMA binders.

1. The results indicated that HL was effective for age-retardation not only in normal binder, but also in PMA binders when they were compared with the large molecular size (LMS). However, identical anti-aging function was not observed from any of liquid additives.

2. In comparison of the estimated stiffness (G*/sin δ) in PMA (76-22) and normal (64-22) binders, stiffness values of HL were significantly lower than those of ASA NO. Therefore, it was concluded that HL was effective on retarding age-hardening of normal binder and PMA binder too.

3. The liquid additives, examined in this study, were not effective at all on retarding age-hardening of PMA binders. Since the liquid additives used in this study showed no effective age-retardation function in PMA binders, it is recommended that the short-term aging level should be investigated before paving when LAs are to be used.

4. However, since this study used a limited number of materials, the conclusion reached in current study is tentative and further investigations are recommended to compare other mixes using other asphalt and aggregates to reach a more generalized conclusion.