1. Introduction

2. Material and test methods

2.1 Base asphalt binder

2.2 Production of CRM asphalt binders

2.3 Preparation of test samples

2.4 Viscoelastic properties and microstructural analysis

2.5 Separation index (SI)

3. Results

3.1 Viscoelastic properties

3.2 Separation index

4. Discussion

5. Conclusion

1. Introduction

Crumb rubber modified (CRM) asphalt binder, created by blending rubber particles from recycled tires into traditional asphalt, improves durability and resistance to diverse factors such as changing temperature and vehicle load (Yu et al., 2021; Chowdhury, 2023). This environmentally friendly solution also contributes to traffic noise reduction (Puccini et al., 2019). Additionally, its use in road pavement and maintenance promises long-term cost savings due to its increased lifespan and reduced need for frequent maintenance, making CRM asphalt an increasingly favourable choice for sustainable infrastructure development (Pouranian and Shishehbor, 2019; Riekstins et al., 2022).

The storage stability issues of CRM asphalt binders primarily stem from the physical and chemical interactions between the crumb rubber particles and the base asphalt. Inconsistency in the binder can arise if the rubber particles do not uniformly disperse within the asphalt matrix, leading to separation and settling during storage (Yun et al., 2022). Therefore, adequate consideration of these storage stability issues is essential in the quality management and application process of CRM asphalt binders. Optimizing factors such as particle size of the rubber, mixing process, and storage conditions is crucial to maintaining the uniformity and performance of the binder (Ren et al., 2020; Vigneswaran, 2023; Yun et al., 2023a; 2023b).

The application of Atomic force microscopy (AFM) in asphalt binder analysis represents a significant leap in pavement material research. AFM, known for its high-resolution imaging, uncovers the surface topography and microstructural phases of asphalt binders, crucial for understanding overall performance (Yang et al., 2020; Zhang et al., 2020; 2022). The focus is on how these microscopic features correlate with the macroscopic behavior of asphalt, particularly its durability and adaptability to environmental stresses (Ouyang et al., 2022). This imaging technology has been employed in several innovative studies to analyze asphalt’s properties and performance. For instance, research has utilized AFM to explore the microscale aging process in asphalt, revealing how exposure to various environmental conditions alters its microstructure (Guo et al., 2021). In another case, AFM was instrumental in understanding the dispersion and effects of nano-materials, such as nano-clays, when added to asphalt, showing improvements in stiffness and resistance to deformation (A Omar et al., 2021). Studies have also focused on the morphology and phase separation in polymer-modified asphalts, where AFM provided insights into the distribution of polymers within the asphalt matrix, crucial for improving its elasticity and durability. Furthermore, AFM has been applied to analyze the interaction between asphalt and aggregate, shedding light on the adhesive properties and moisture damage potential (Ozdemir et al., 2021). These applications of AFM in asphalt analysis underscore its utility in enhancing our understanding of asphalt at a microstructural level, leading to more effective and durable pavement solutions.

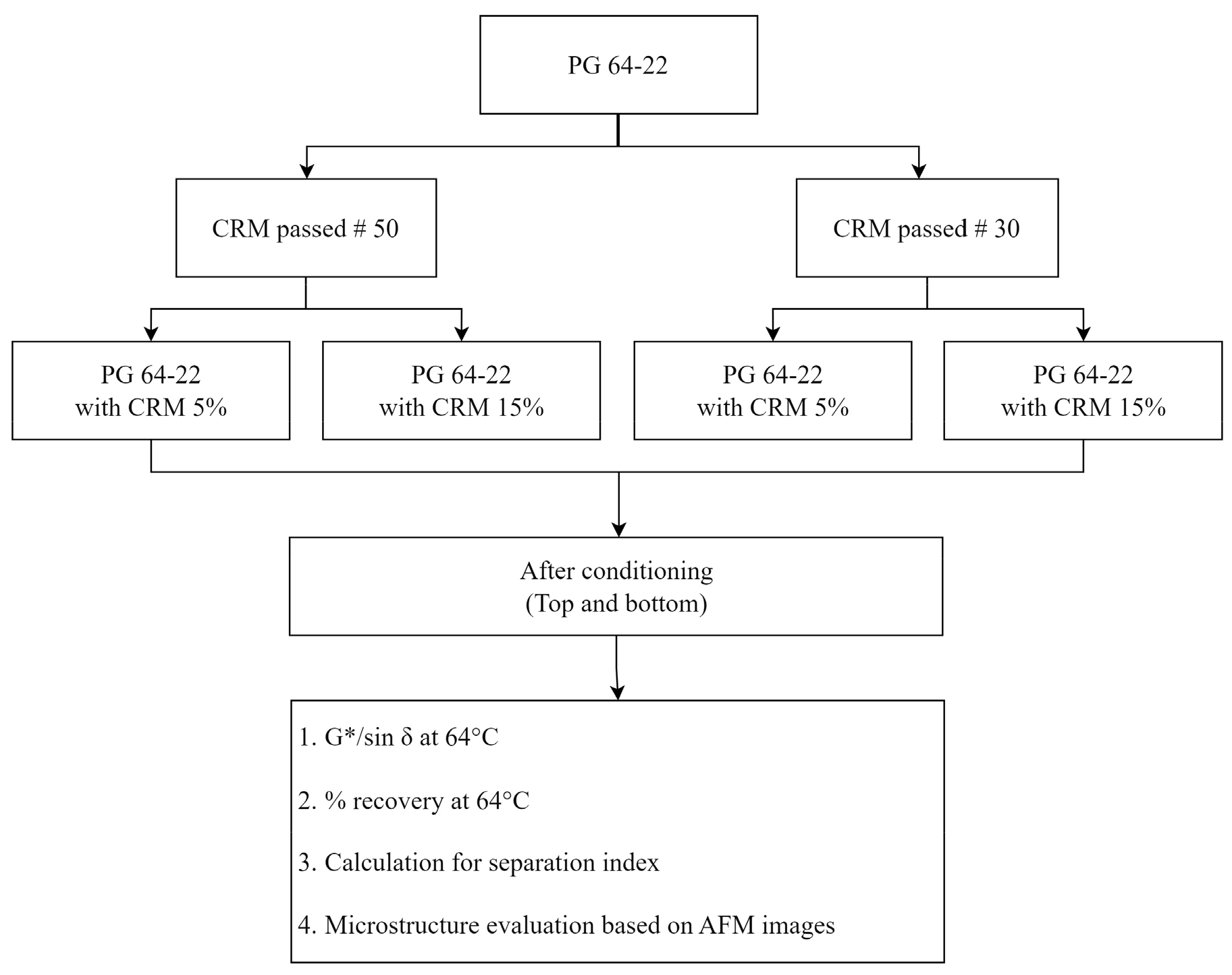

The aim of this research is to comprehensively analyze the viscoelastic properties and microstructural features of asphalt binders modified with different types of CRM using both mechanical testing and AFM. The focus is to understand how variations in CRM particle size and content affect the overall performance and stability of asphalt binders. Specifically, the impact of #50 and #30 CRM particles was investigated, assessing their influence on the binder’s viscoelastic properties, such as G*/sin and % recovery, and their correlation to the SI between the data of physical properties and surface images. In addition, the goal is to provide insights into the potential of using different types of CRM in asphalt binders for improved road pavements. Fig. 1 shows the flow chart of this study.

2. Material and test methods

2.1 Base asphalt binder

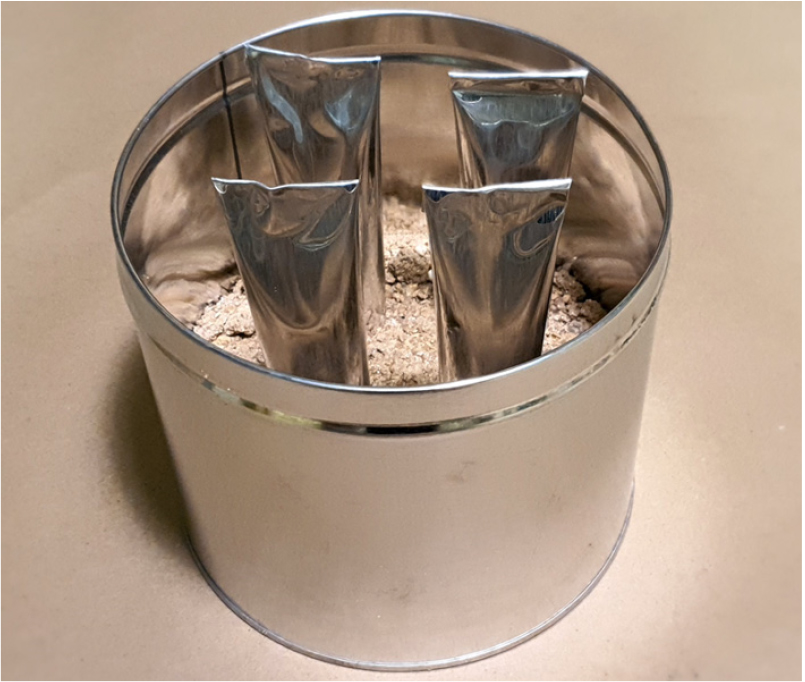

The base binder for this study was a Performance grade (PG) 64-22 asphalt binder, which was modified with CRM. The specific properties of this asphalt binder and the particle size distribution of the crumb rubber are detailed in Tables 1 and 2. Additionally, Fig. 2 illustrates the aluminum tube, as suggested in ASTM D7173, to assess the storage stability of the modified binder in this research.

Table 1.

Properties of the base asphalt binder (PG 64-22)

Table 2.

Gradation of each CRM utilized in this study

| Sieve number | Passing rate (%) | |

| CRM passed # 50 | CRM passed # 30 | |

| # 30 | 100 | 88.0 |

| # 50 | 33.3 | 16.5 |

| # 100 | 12.2 | 3.2 |

| # 200 | 1.9 | 0.4 |

2.2 Production of CRM asphalt binders

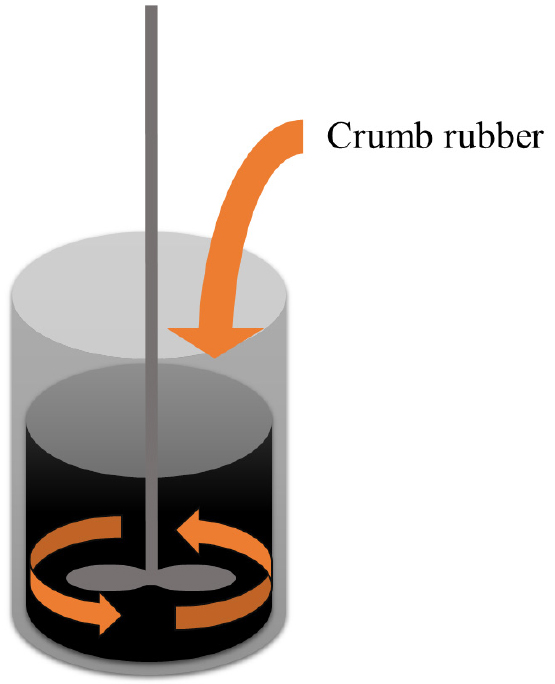

In this study, the CRM asphalt binder was created using the wet process technique. This method involved a thorough mixing of the binder at a speed of 700 rpm for 30 minutes using an open-blade mixer (as depicted in Fig. 3), all while maintaining a steady temperature of 177°C, following the guidelines (Lee et al., 2006; Shen et al., 2006). The modified binder was produced by adding different amounts of crumb rubber, specifically 5% and 15% by the weight of the base binder to achieve a comprehensive understanding of the CRM asphalt binder’s properties. To maintain uniformity in the binder’s composition throughout the study, only a single batch of crumb rubber was used. This strategy helped eliminate potential variations and inconsistencies that could have arisen from using multiple batches of crumb rubber, thus ensuring a more precise and reliable assessment of the binder’s performance.

2.3 Preparation of test samples

Before pouring into a vertically aligned tube as per ASTM D7173 standards, the CRM binder sample was thoroughly stirred. Approximately 50 ± 0.5 g of the binder was then transferred into the tube. The tube, sealed and containing the CRM binder, was kept upright and conditioned for 48 hours at a temperature of 163 ± 5°C, as illustrated in Fig. 4. Post-conditioning, the tube was quickly moved to a freezer set at -10 ± 10°C, maintaining its vertical orientation throughout. A minimum four-hour freezing period ensured the binder’s complete solidification. Once solidified, the tube was taken out, placed on a flat surface, and equally segmented into three parts. Each segment was then heated in an oven at 163 ± 5°C until the asphalt softened sufficiently to remove the aluminum casing, all within 30 minutes. The softened binder from each segment was then readied for further analysis and testing.

2.4 Viscoelastic properties and microstructural analysis

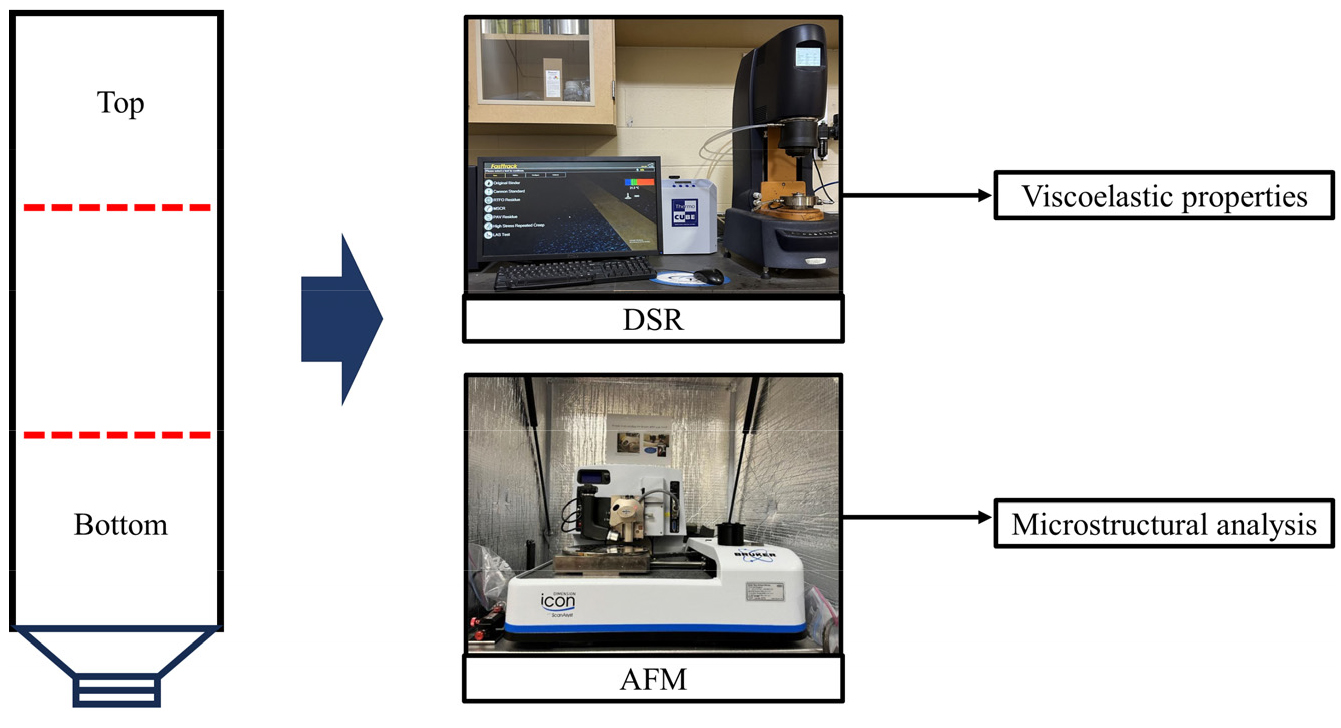

To assess the viscoelastic characteristics of each section, the Dynamic shear rheometer (DSR) was used to examine the CRM binders’ viscoelastic properties, focusing on determining the G*/sin value and % recovery. G*/sin was ascertained by measuring the complex shear modulus (G*) and the sine () of the phase angle, while % recovery was measured using the Multiple stress creep and recovery (MSCR) test. Both tests were carried out at a consistent temperature of 64°C.

To investigate the micromorphology and surface features of CRM binders, the Bruker dimension icon AFM was employed. Surface images were taken from binder samples prepared through the heat-cast method, enabling detailed topographical analysis. This method involves pouring hot asphalt binder into a mold, cooling it at room temperature, and then testing it. Tapping mode was selected for image acquisition, suitable for soft, adhesive samples, using the HQ: NSC14/Al BS probe, effective for soft samples. The AFM operated at 0.5 Hz scanning speed, capturing images of 20 µm × 20 µm.

2.5 Separation index (SI)

This research focused on assessing the rheological characteristics of CRM asphalt binders to calculate the Separation index (SI) of both the upper and lower sections of the samples. The evaluation of SI was based on G*/sin and % recovery, as defined in Equations (1) and (2). The study involved a comparative analysis of SI values derived from these two methods. Additionally, an in-depth analysis was performed by linking the AFM images with the binder’s rheological properties and SI, providing greater insight into the microstructure of the binder and its impact on its rheological properties. Fig. 5 represents the concept for SI.

3. Results

3.1 Viscoelastic properties

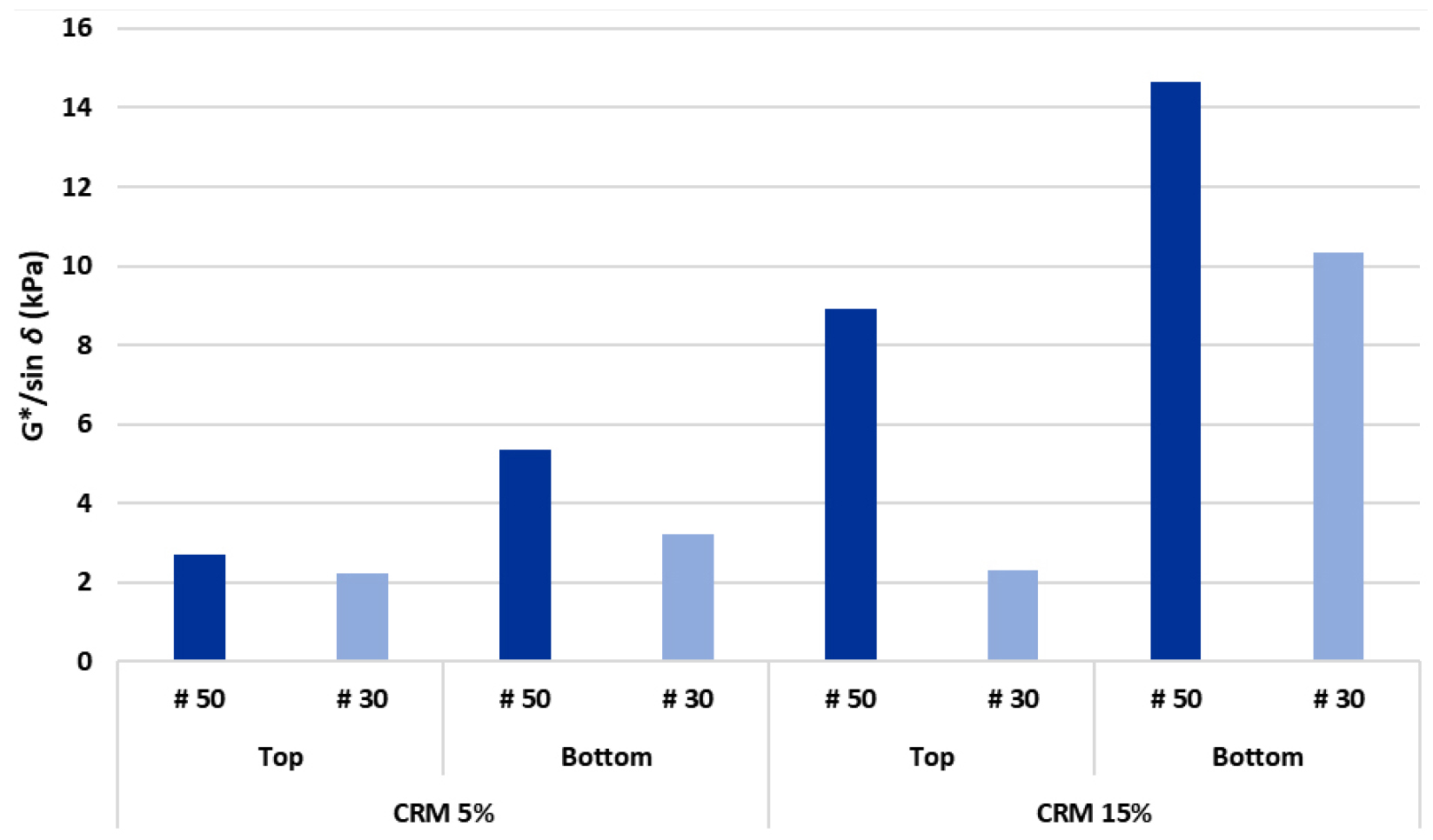

3.1.1 G*/sin

In general, the G*/sin measurement indicated higher values, particularly in the lower parts among all CRM contents as shown in Fig. 6. This is interpreted as being due to the difference in density between CRM and the base asphalt. Notably, the data of # 50 CRM asphalt binders exhibited marginally higher values compared to that of # 30 CRM asphalt binders. This difference was most pronounced at the top layer with 15% CRM content, where the results of # 50 CRM asphalt binders demonstrated a value more than four times greater than the data of # 30 CRM asphalt binders. This significant disparity is attributed to the CRM’s larger specific surface area, resulting from the inclusion of smaller-sized CRM particles that pass through a #50 size sieve. The result is that CRM with a larger specific surface area absorbs light oil and expands itself, with smaller differences in density of based asphalt binder and CRM asphalt binder, thereby exerting a uniform influence on both the top and bottom sections of the asphalt binder. Consequently, # 50 CRM asphalt binders, which recorded relatively higher measurements, had higher contents of smaller particle CRM. These finer CRM particles were less influenced by variations in binder and density, allowing them to impact the data up to the upper layer of the material. This phenomenon contributed to the observed results.

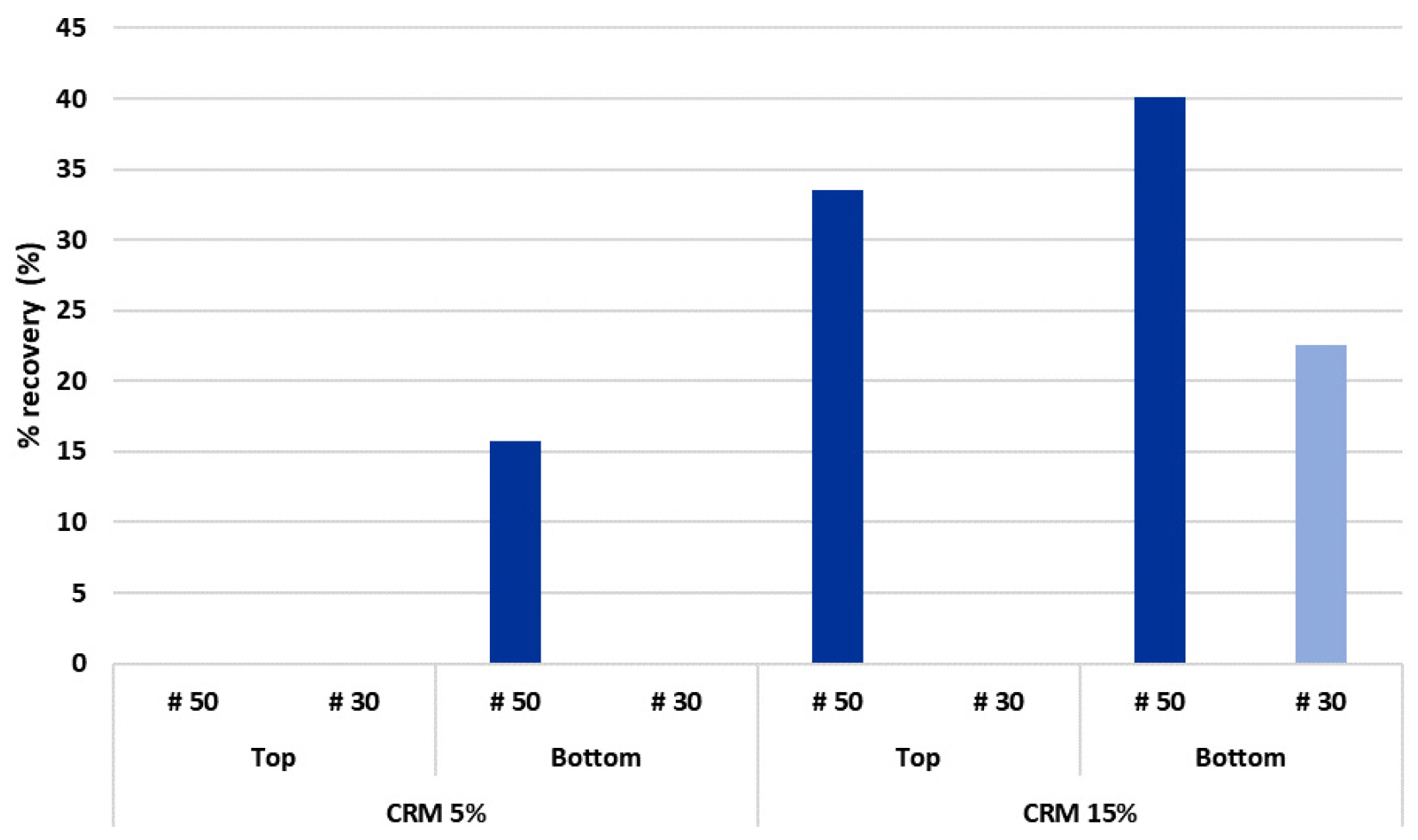

3.1.2 % recovery

The % recovery outcomes were determined using the MSCR test, a method for assessing the viscoelastic properties of asphalt binder (Fig. 7). The MSCR method’s higher load factor of 3.2 kPa led to some samples being unmeasurable. Specifically, for # 30 CRM asphalt binders, measurements were only taken from the bottom part at 15% CRM content. In contrast, for # 50 CRM asphalt binders, all samples except for the top part at 5% CRM content were measured, additionally showing a marginal difference between the results of the top and bottom parts at 15% CRM content. The comprehensive measurement of higher % recovery in # 50 CRM asphalt binders is primarily attributed to the smaller particle size, as previously indicated in the G*/sin findings. The smaller size of CRM particles with a larger specific surface area is considered to be less impacted by density differences, also leading them to absorb oil, expand, and enhance the overall viscoelasticity of both the upper and lower parts. Nevertheless, the MSCR test’s condition for higher load limited some data acquisition, suggesting that this method might not be accurate for this study.

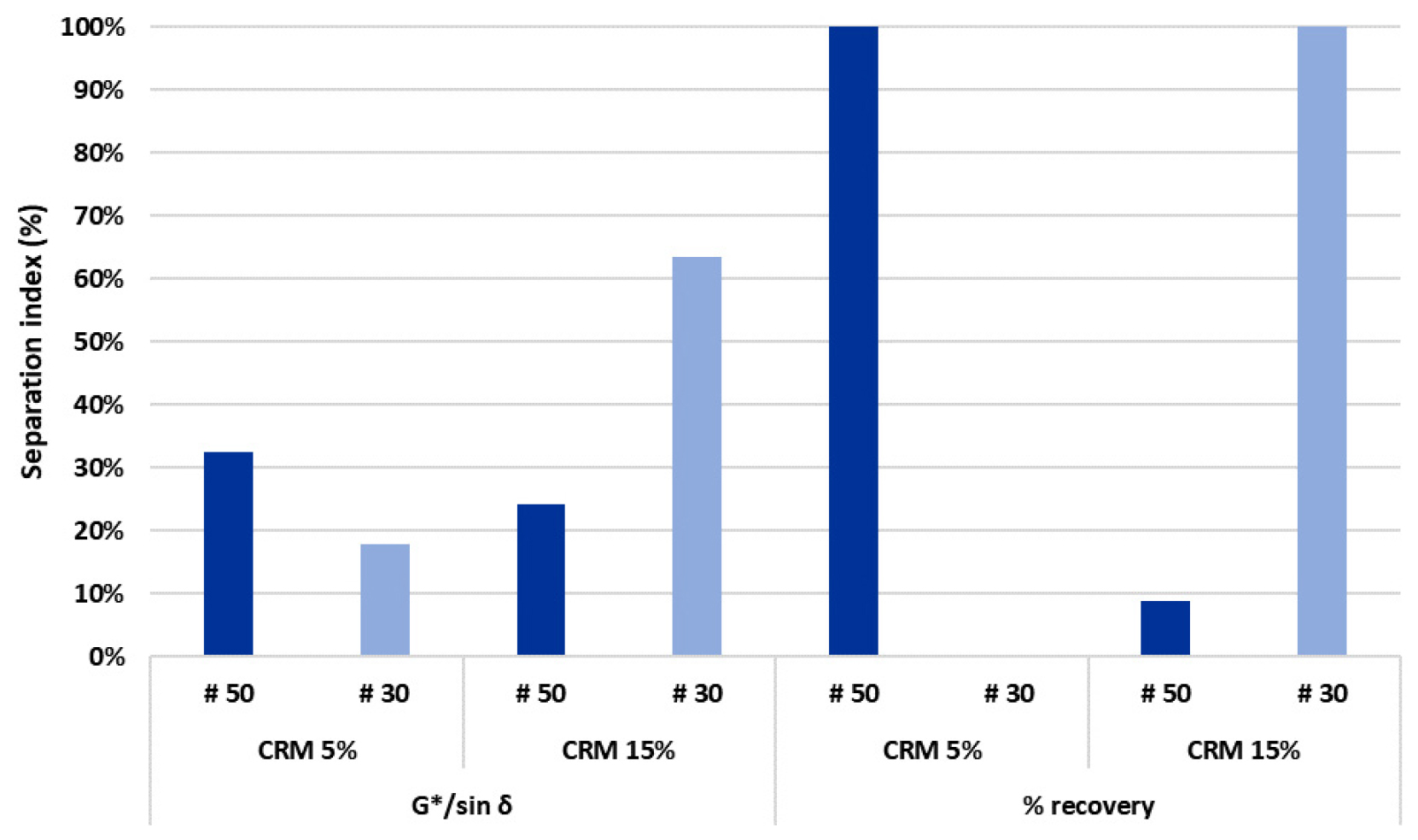

3.2 Separation index

3.2.1 Separation index from physical properties

In order to assess the SI, data of G*/sin and % recovery were taken from both the top and bottom parts of the CRM asphalt binder. As it is shown in Fig. 8, the SI derived from the 5% CRM binder’s G*/sin revealed that # 50 CRM asphalt binders yielded higher results compared to the # 30 CRM asphalt binders. This disparity is attributed to the more pronounced viscoelasticity in both the upper and lower sections of the # 50 CRM asphalt binders, which was reflected in the SI data. Conversely, the # 30 CRM asphalt binders displayed negligible differences, as the viscoelastic properties of the upper and lower binder data were minimal. Regarding SI results based on % recovery, the measurements for # 50 CRM asphalt binders were not evaluated due to the high loads involved. When examining SI using G*/sin of 15% CRM asphalt binder, it was found that # 50 CRM asphalt binders had an SI approximately two times lower than that of # 30 CRM asphalt binders. This difference is thought to arise from the smaller particle size of # 50 CRM asphalt binders, which is less influenced by density variations and affects the binder more uniformly from bottom to top parts. On the other hand, # 30 CRM asphalt binders exhibited a higher SI due to a significant discrepancy between the upper and lower parts, as the settled CRM particles predominantly impacted the lower section. This trend was also evident in the % recovery results, where # 50 CRM asphalt binders showed an SI value more than ten times lower. Therefore, it was concluded that the size of CRM particles influences the SI, with a higher content of small-sized particles correlating to a lower SI.

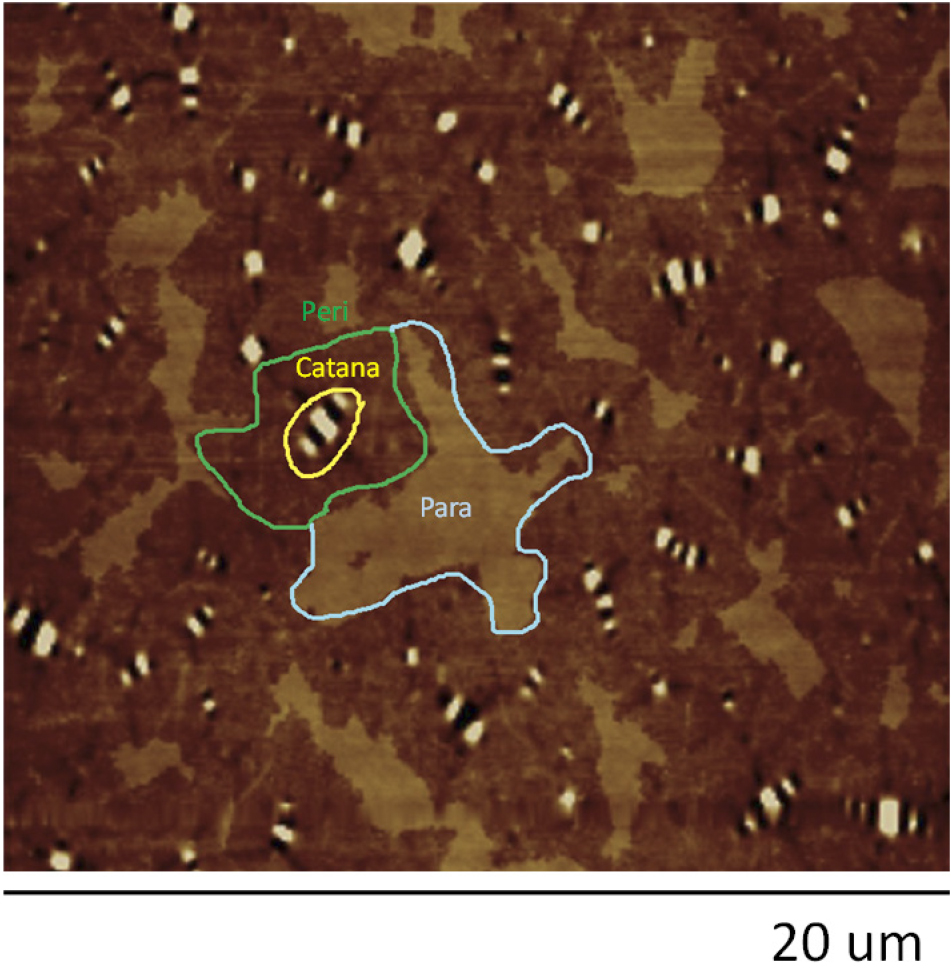

3.2.2 Separation index from AFM images

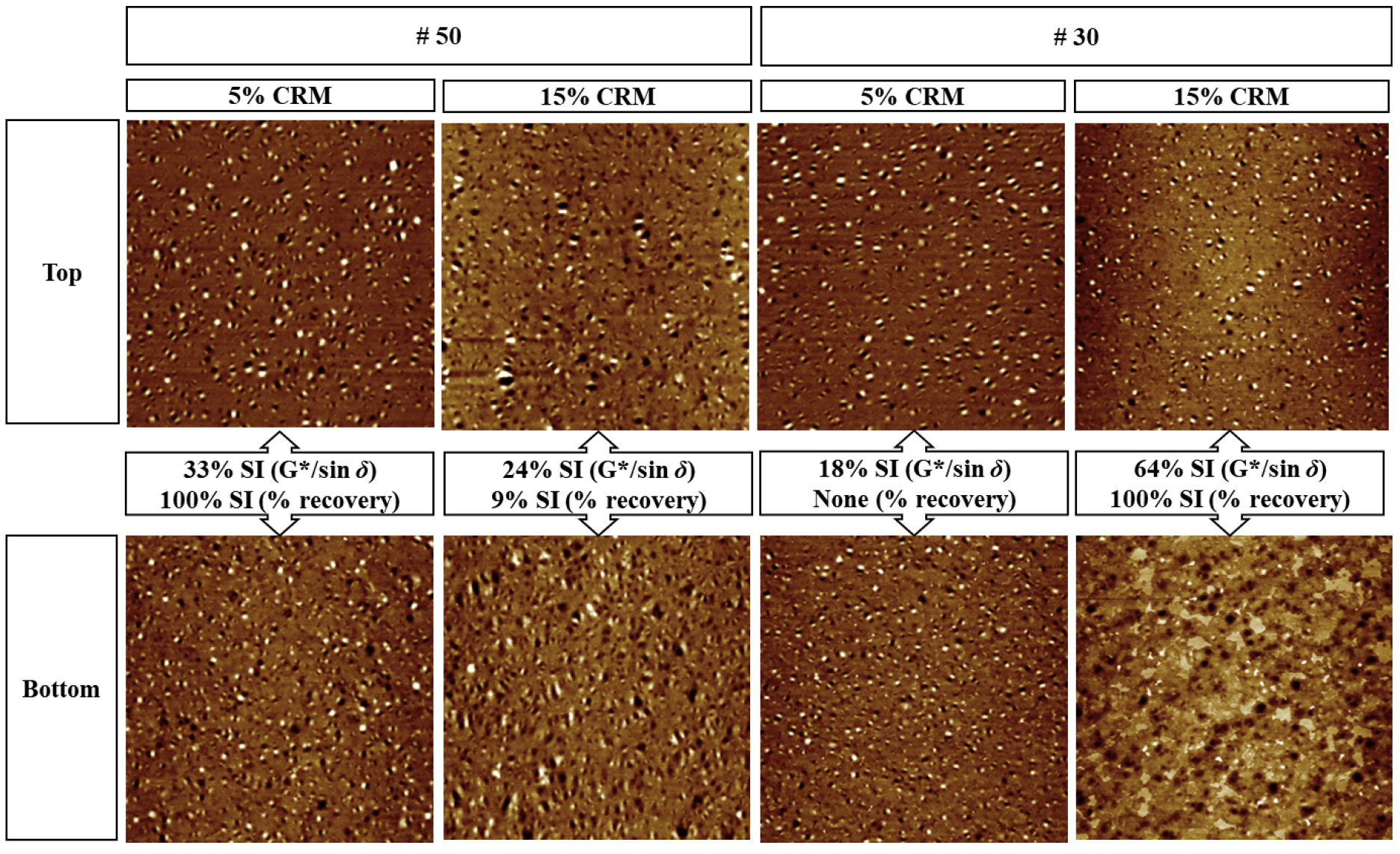

AFM imaging was utilized to acquire a topographical base image of the PG64-22 binder to compare it to CRM asphalt binder. The AFM images were examined to understand the microstructure and surface features of the binder. In earlier studies, unique bee-like structures were noted as elongated areas with crosswise striping of variable surface heights (Loeber et al., 1996). This unique structure, known as the catana phase, is generally encircled by a level peri phase, which is further bordered by a distinct para phase (Masson et al., 2006; Hung and Fini, 2015). Fig. 9 in this study presents an example of these microstructural characteristics as defined in prior research. Additionally, in this image, the bee-shaped structure, along with peri and para phases, was evident in the PG64-22 asphalt binder utilized in this research. Following these observations, an analysis of the surface structure of the CRM asphalt binders and PG64-22 binder was conducted concerning SI, particularly after undergoing conditioning to assess storage stability.

The CRM asphalt binder’s surface was examined utilizing the AFM image of PG64-22 asphalt binder (Fig. 10). It was observed that CRM asphalt binders generally had a reduced and diminishing catana phase. Furthermore, an increase in CRM content correlated with a rise in the para phase. For asphalt binders with 5% CRM content, top and bottom surface images were consistent across binders from both particle sizes, yet the bottom parts exhibited a more pronounced increase in the para phase. On the other hand, with 15% CRM content, the top and bottom images for sources from # 50 CRM asphalt binders were uniformly similar, while the # 30 CRM asphalt binders displayed a distinct top-bottom contrast. Notably, the # 30 CRM asphalt binders exhibited a significant increase in the para phase at the bottom. These image-based SI analytical findings paralleled those from physical experiments, indicating that a higher SI value corresponds to a more pronounced discrepancy between the top and bottom images. Therefore, these results suggest the possibility of SI analysis through images of asphalt binders.

4. Discussion

The outcomes in this study revealed that as the CRM content increased and shifted towards the lower portion, a noticeable accumulation of CRM particles became apparent. This accumulation exerted a significant influence on the overall behavior of the binder properties, a phenomenon that is also observable in the AFM images. One of the principal findings involved the relationship between CRM content and changes in viscoelasticity. With an increasing concentration of CRM, the viscoelasticity of the asphalt binder increased, a pattern that corresponded with the changes witnessed in the AFM images. As the CRM content increased from 5% to 15%, the distinct bee-shaped features in the topographical image gradually lost clarity, giving rise to a black dot near the lower region, signifying changes in the topographic image and a more pronounced impact on CRM. Furthermore, as CRM content increased, the para phase expanded in the topographic images, further substantiating the notion that AFM images effectively illustrated changes in the binder’s physical properties. To summarize, these findings underscore the close connection between CRM content, changes in physical characteristics, and AFM topographic representations. It is evident that as CRM content rises, AFM images depict the evolving physical attributes of the binder in detail. Consequently, AFM topographic images can serve as an efficient instrument for the storage stability of CRM asphalt binders. The capacity to visually evaluate binders through AFM imaging contributes valuable insights to the comprehension of asphalt binder properties.

5. Conclusion

The comprehensive analysis of the viscoelastic properties and microstructural features of asphalt binders modified with CRM (5% and 15%) sourced from two types of CRM, utilizing both mechanical testing and AFM, has yielded insights into the material behavior and SI.

1. G*/sin values were higher, especially in the lower parts of asphalt binders with different CRM contents, due to the different densities between CRM and base asphalt. # 50 CRM asphalt binders showed marginally higher values than the data of # 30 CRM asphalt binders. This is linked to the larger specific surface area of # 50 CRM, derived from smaller-sized particles. These finer particles absorb light oil and expand, reducing density differences between the base and CRM binders, thereby uniformly affecting the binder’s entire section.

2. The MSCR test revealed that the % recovery of CRM asphalt binders was higher for those with # 50 CRM, likely due to their smaller particle size and larger specific surface area where the CRM reacts with base asphalt binder. However, the test’s high load factor restricted data collection, particularly for # 30 CRM asphalt binders, where only the bottom part at 15% CRM content could be measured. This suggests potential inaccuracies of the MSCR test under high load conditions, especially when evaluating the uniformity of viscoelastic properties across diverse binders.

3. The SI assessment, using G*/sin and % recovery data from CRM asphalt binders, indicated that # 50 CRM asphalt binders had enhanced viscoelasticity and lower SI values compared to their counterparts from the # 30 CRM asphalt binders. This was particularly true for binders with smaller CRM particles, which displayed a more uniform distribution and influence throughout the binder layers. # 30 CRM asphalt binders showed a higher SI, suggesting less uniformity, primarily due to larger particle sizes settling more at the bottom. The findings imply that smaller CRM particles result in a lower and more consistent SI across the binder.

4. Binders modified with 5% CRM content showed similar top and bottom surface features in samples from both types of CRM, although the para phase was more distinctly enhanced in the lower sections. For 15% CRM content, samples from # 50 CRM asphalt binders maintained similar between the top and bottom layers, whereas samples from # 30 CRM asphalt binders showed significant differences, highlighting a disparity in phase distribution. These observations from AFM images align with physical experiment data, suggesting that higher SI values are linked to greater differences between images. This confirms the feasibility of using AFM images for SI analysis in asphalt binders.

5. This research examined the SI by analysing AFM images and physical characteristics, focusing on the use of CRM modifiers. For a more efficient application of SI analysis through imaging techniques in future studies, it is suggested that investigations incorporating a diverse range of modifiers should be conducted. This approach will potentially enhance the understanding and accuracy of SI assessments in different contexts.

6. Furthermore, it should be noted that this study exclusively focuses on asphalt binders. Consequently, to achieve a better comprehension of the subject, it is considered that future investigations explore the connection between the surface image of binders and the characteristics of asphalt mixtures.