1. Introduction

2. Research Objective

3. Specified pavement section selection process

4. Asphalt Mixture Coring and Performing Fracture Experimental Work

5. Theoretical Background of Semi-Circular Bending (SCB) Test

6. Data Analysis

7. Summary and Conclusion

1. Introduction

In northern U.S. and South Korea, one of the crucial distresses in asphalt pavement field is low temperature cracking (Moon, 2010; 2012). During cold weather session, thermal stress is developed in inner layer of asphalt pavement. If the temperature level dropped to critical cracking temperature level, the stress in inner pavement layer is then released. Finally, crack occurs in transverse manner on pavement surface and this is called low temperature thermal cracking (Moon et al., 2014). Due to thermal cracking, various pavement distresses on asphalt can happen such as: deformation, pot hole and several corresponding macro cracks on surface (Marasteanu et al., 2009). Therefore, development of reasonable pavement surface condition monitoring technologies including equipment is crucial.

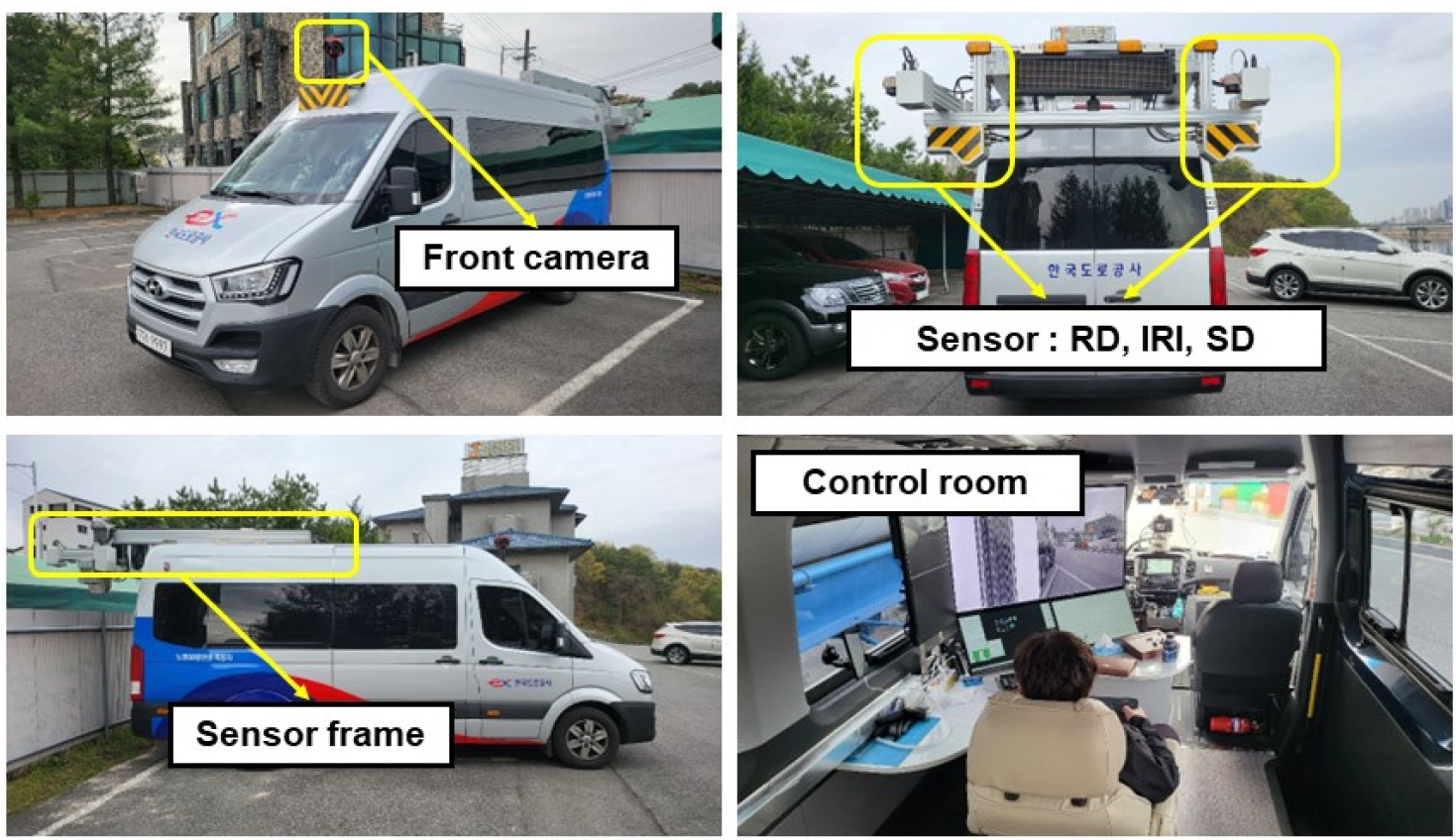

Along with application of Highway Pavement Management System (HPMS), development of advanced pavement surface monitoring system has been considered since early 2000. One of remarkable achievement is: development of 3D Pavement condition Monitoring profiler vehicle (3DPM) (Sohn et al., 2018; 2021). Fig. 1 presents the schematic information of current 3DPM equipment originally designed and developed in KEC.

Thanks to 3DPM approach, various major pavement distresses such as rutting (for asphalt pavement), cracking (for asphalt and concrete pavement) and surface smoothing quality (for asphalt and concrete pavement) can easily be surveyed with high quality of image capturing technology (Sohn et al., 2018; 2021). It means most of low temperature cracking on asphalt pavement surface can successfully detected and analyzed by 3DPM approach.

However, one major limitation (and/or drawback) of 3DPM is: this equipment can monitor surface condition of given pavement only. It means low temperature performance of whole asphalt pavement layer cannot be fully analyzed by means of 3DPM which gives some concerns of its feasibility. Therefore, extensive experimental work and corresponding analysis are recommended to further strengthen the feasibility of 3DPM approach.

2. Research Objective

The major objective of this paper is: strengthen and verify the feasibility of current 3DPM approach. To achieve the goal, the following activities were taken:

1. A specified pavement section where is expected to be relatively weak on thermal cracking resistance, was selected then monitored by means of 3DPM approach.

2. Secondly, a pavement mixture coring work was done for further experimental activities.

3. Semi Circular Bending (SCB) test (Li and Marasteanu, 2004; Li, 2005; Li et al., 2008; Cannone Falchetto et al., 2017), was performed to measure low temperature properties of asphalt mixture at -22°C.

4. Two mechanical performance parameters, fracture energy (Gf) and fracture toughness (KI) were calculated then compared (Li and Marasteanu, 2004; Li, 2005; Li et al., 2008; Cannone Falchetto et al., 2017).

5. The feasibility of current 3DPM approach was evaluated and conclusion was finally derived.

3. Specified pavement section selection process

One specified pavement section: where good and bad pavement sections co-exist, around Busan territory was selected. Then 3DPM equipment was applied to monitor pavement surface condition (Sohn et al., 2018; Sohn et al., 2021). Fig. 2 and Table 1 shows the information of selected pavement site in this paper.

The extensive pavement surface condition index such as Highway Pavement Condition Index (HPCI), International Roughness Index (IRI, m/km), Rut Depth (RD, mm) and Surface Damage (SD,%), were monitored then computed by means of current 3DPM equipment. More detailed information on pavement surface index can be referred in elsewhere (MOLIT, 2013; Road Korea Pavement Research Team, 2023).

The monitored pavement section is consisted of two sub sections: good (i.e. HPMS grade is 1 to 2) and bad section (i.e. HPMS grade is 4 to 5). The detailed information on monitored pavement section is given in Table 1.

From Fig. 2 and Table 1, it can be found that good and bad asphalt pavement section can easily and reasonably distinguished b y means of current 3DPM approach. However, the inner pavement layer condition cannot fully be understood if only 3DPM approach is applied. If the physical correlation between pavement surface condition (i.e. monitored by 3DPM) and inner pavement layer performance can be found, it can be said that the current 3DPM approach contains strong feasibility on pavement monitoring area. Therefore, the additional experimental work was considered. More detailed information is provided in the next section.

Table 1.

Detailed information of selected pavement section (AASHTO M320-10, 2010)

| Section | Asphalt mixture | HPCI |

IRI (m/km) |

RD (mm) |

SD (%) |

|

Section A (Good) |

HMA (13 mm) PG 64-22 | 1~2 | 2.0 | 1.5 | 0 |

|

Section B (Bad) |

HMA (13 mm) PG 64-22 | 4~5 | 3.3 | 2.5 | 2.3 |

4. Asphalt Mixture Coring and Performing Fracture Experimental Work

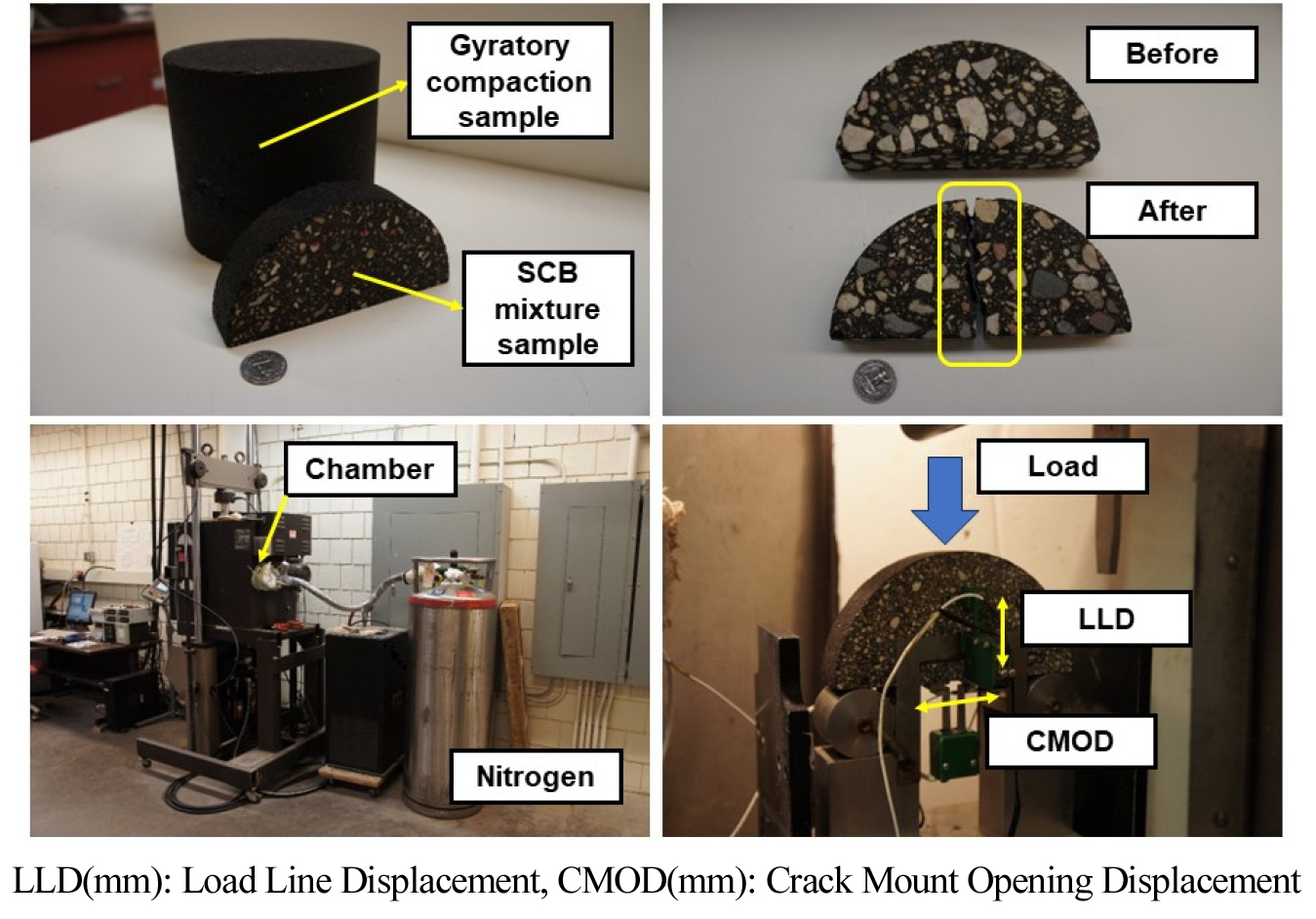

To evaluate low temperature fracture performance of cored asphalt mixture, Semi Circular Bending (SCB) test, was considered in this paper (Li and Marasteanu, 2004; Li, 2005; Li et al., 2008; Cannone Falchetto et al., 2017). The following procedure was performed as follows:

1. Asphalt mixture cores were acquired in the selected pavement section shown in Table 1. In each section, three asphalt mixture cores were acquired. Therefore, total six asphalt mixture cores were acquired.

2. All the asphalt mixture cores were sent to Aalto university (Finland) pavement research laboratory. Then the mixtures were prepared for SCB (Li and Marasteanu, 2004; Li, 2005; Li et al., 2008; Cannone Falchetto et al., 2017). A schematic picture of SCB testing procedure is illustrated in Fig. 3.

3. The testing temperature conditions were set as -22°C in this paper.

4. Finally, two mechanical properties: fracture energy (Gf) and fracture toughness (KI) were computed then compared. More detailed information about Gf and KI are shown in next section.

5. Theoretical Background of Semi-Circular Bending (SCB) Test

A special servo-hydraulic testing system along with an environmental temperature controlling chamber is used in SCB low temperature fracture test (Li and Marasteanu, 2004; Li, 2005; Li et al., 2008). In case of SCB test, test specimen dimension is consisted of 25 mm of thickness and 75 mm of radius, respectively. Then the test sample is supported by two fixed rollers and contains a span of 120 mm, symmetrically. In this test, Load Line Displacement (LLD, mm) result is recorded with a vertically mounted extensometer with 38±1 mm gage length measuring applicability. It needs to be mentioned that another displacement measuring sensor is attached to a metal button glued to the sample for measuring a constant Crack Mouth Opening Displacement (CMOD) with displacement rate change of 0.0005 mm/s. A contact amount of load (maximum value: 0.3 kN) is applied before the actual loading to ensure uniform contact between the loading plate and the specimen. The SCB testing procedure is stopped when the load dropped to 0.5 kN in the post peak region. All the test procedure is performed inside the specified environmental chamber with liquid nitrogen cooling tank (see Fig. 3).

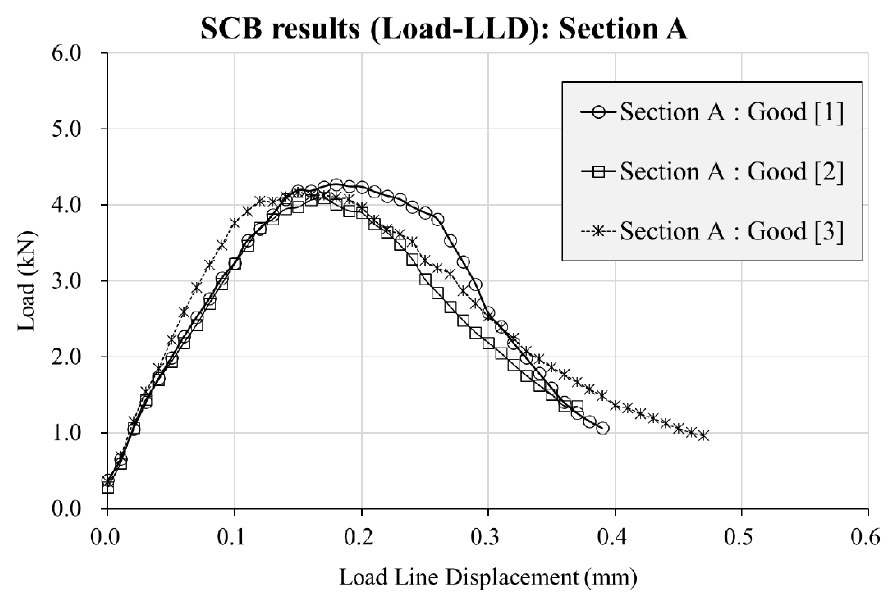

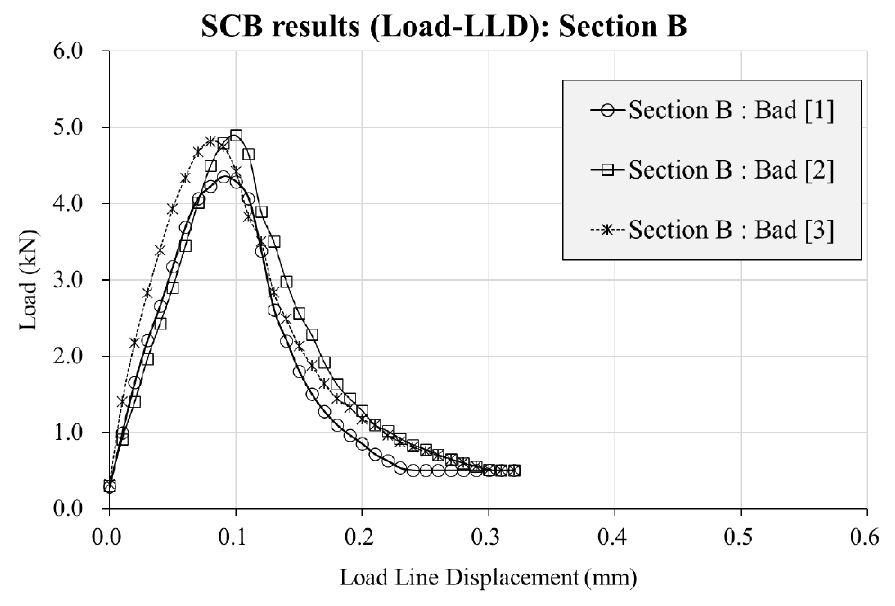

Finally, the load (y-axis) and Load Line Displacement (P-u:LLD, x-axis) curve is generated as test result in SCB fracture test. These data set are used to compute low temperature fracture performance of asphalt mixture: fracture toughness: KI, and fracture energy: Gf.

First, the stress intensity factor (fracture toughness): K is calculated using the following equation on liner-viscoelastic condition as mentioned in the previous research (Li, 2005; Li and Marasteanu, 2008). The mechanical parameter computation process is shown in Equations (1), (2), (3), (4), (5).

Where, KI = Mode I stress intensity factor (Li, 2005; Cannone Falchetto et al., 2017),

P = applied load,

r = specimen radius (=75 mm),

t = specimen thickness (=25 mm),

YI = the normalized stress intensity factor,

Ci = constants,

a = notch length (20 mm),

= actual span ratio,

= nearest span ratio analyzed in the derivation of this equation (0.80, 0.67, 0.61, 0.50)

Secondly, the fracture energy Gf was calculated regard to the previous references (Li, 2005; Li et al., 2008; Cannone Falchetto et al., 2017). The work of fracture is the area under the loading-deflection (P-u) curve. Finally, the fracture energy: Gf, can then be obtained by dividing the work of fracture with the ligament area as can be seen in Equations (6) and (7).

In Equations (6), (7), Wf and Alig mean the work of fracture and the area of the ligament, respectively. At each temperature condition, three samples were used to compute the fracture toughness: KI, and fracture energy: Gf. Therefore, total 6 samples were used in this paper.

6. Data Analysis

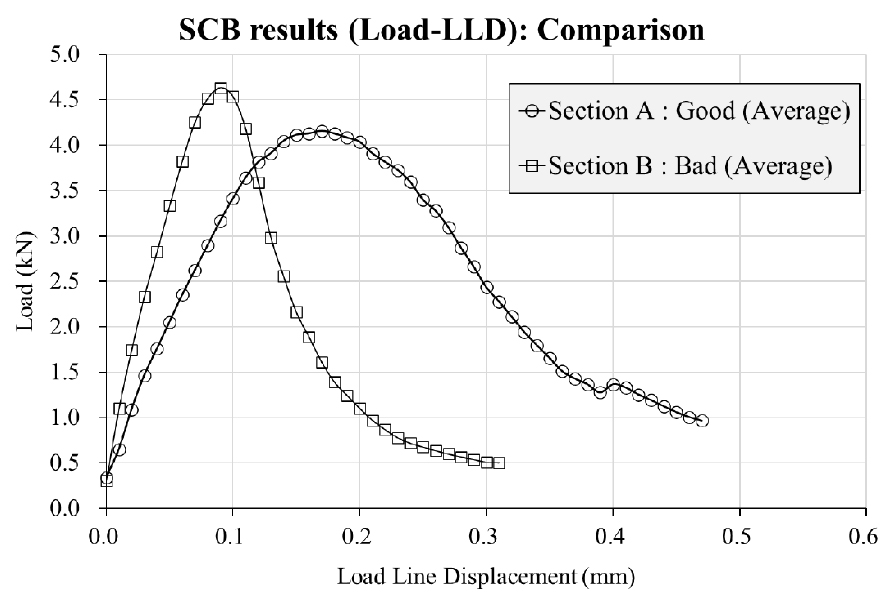

The experimental results of SCB test are presented in Figs. 4, 5, 6 and Table 2, respectively.

From the results, it can be said that remarkable fracture property differences on selected asphalt mixture were found as expected in the previous surveying work. This means the current pavement surface monitoring equipment: 3DPM, can successfully distinguish the selected asphalt pavement low temperature fracture performances. However, only one pavement section was considered in this study due to limited testing condition. More extensive experimental works along with further analysis efforts are needed to further strengthen the findings in this research.

7. Summary and Conclusion

In this paper, asphalt mixture coring work with simple performance test named SCB mixture fracture test were performed to further verify the detecting ability of 3DPM equipment. Remarkable asphalt mixture fracture performance differences were found as expected. As a result, it can be mentioned that the current 3DPM approach can evaluate not only the expressway surface condition but also the corresponding inner layer pavement performance quality. However, more extensive experimental work along with analysis procedure is recommended to further verify and strengthen the findings in this paper.