1. Introduction

2. Materials and Methods

2.1 Materials

2.2 Methods

3. Results and Discussions

3.1 Rut depth

3.2 Dynamic stability

4. Conclusions

1. Introduction

Asphalt is used widely in construction such as building, road and railway etc. asphalt concrete track has been studied and applied to the fields worldwide (Lee et al., 2017). The surface of asphalt concrete is pressured directly in the road, but the railway is not because of sleeper. Therefore, there is a need that new permanent deformation estimate method should be suggested because of the different condition (Na et al., 2013; Na et al., 2019).

There is a risk if permanent deformation is caused by temperature increase, because the asphalt binder is used as a compound to increase the cohesion between aggregate in railway (Roberts et al., 1999). Recently, the temperature is continuously increasing due to the abnormal temperature caused by global warming, according to the weather center. The pavement temperature is defined over 60℃ depend on Strategic highway research program(SHRP)-A-410 standard due to high temperature 41℃ on August, 2018 according to weather center (Na et al., 2019). In other words, the test temperature which is one of the important factor during indoor permanent deformation measurement of asphalt compounds is needed to redefine.

In this study, with two temperature conditions, 60℃ and 65℃, the permanent deformation resistance evaluation of asphalt mixture and the optimal temperature condition are suggested by MWTT (Modified wheel tracking test) method for railway.

2. Materials and Methods

2.1 Materials

2.1.1 Asphalt

In this study, two types of PG 64-22 grade, AP-5, styrenic thermoplastic elastomer (STE) asphalt binders, and 2 types of PG 76-22 grade, crumb rubber modifier (CRM), and Styrenic Thermoplastic Elastomer (STE5) modified asphalt binders, are used for the study and their properties are shown in Table 1.

Table 1. Asphalt Binder Property

2.1.2 Aggregate

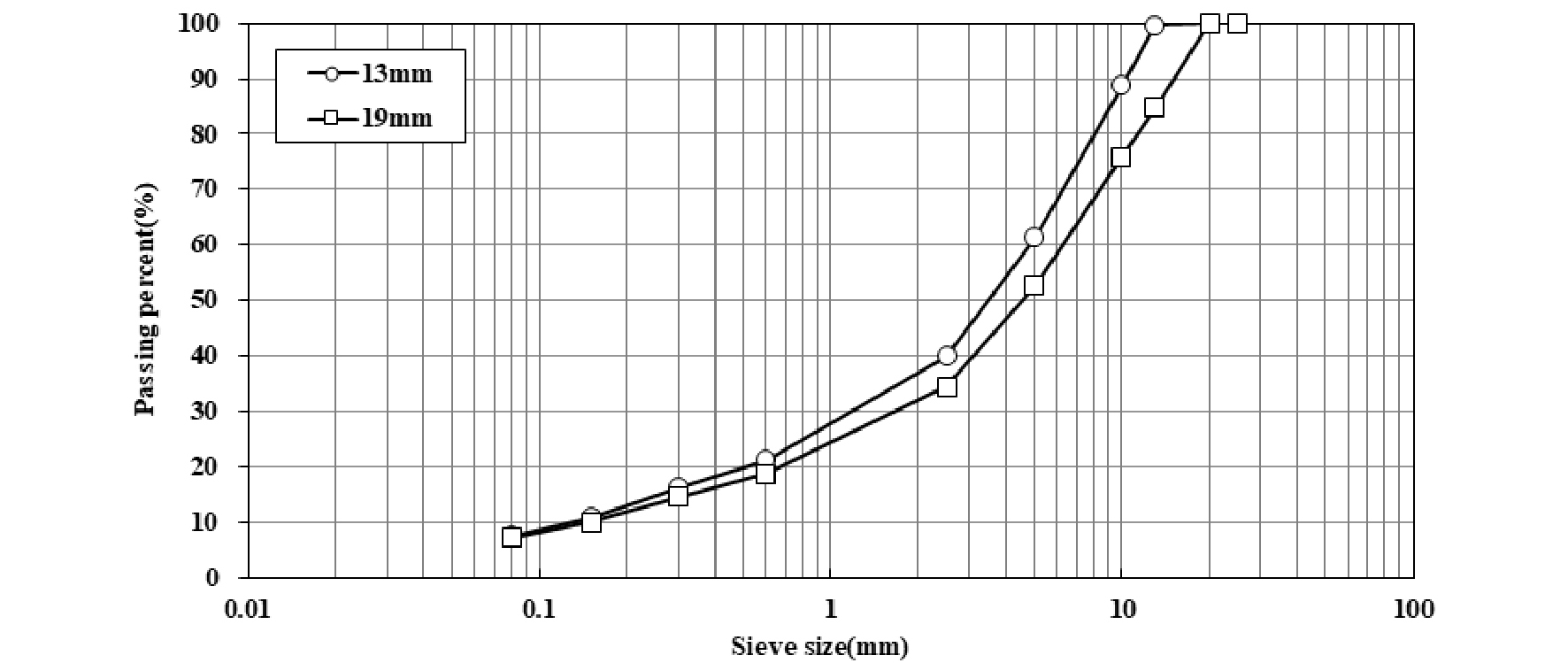

In this study, 13 mm, 19 mm coarse aggregate and fine aggregate which is Granite from Chung-buk are used and limestone is used as a filler. Their properties are measured in accordance with KS (Korean Industrial Standards) and are shown in Table 2.

The coarse aggregate maximum size used in the asphalt mixture is 19 mm, 13 mm and the density asphalt mixture is made as shown Fig. 1. The air void was set to 1~3% by mix design based on the asphalt concrete track construction standard which is using for Baekwon station.

Table 2. Aggregate Property

| Classification | Apparent specific gravity (g/cm3) | Absorption (%) | Abrasion (%) |

| Specification | > 2.5 | < 3.0 | < 40 |

| 19 mm | 2.71 | 1.33 | 30.7 |

| 13 mm | 2.65 | 0.81 | 19.5 |

| Fine agg. | 2.67 | 1.01 | 30.7 |

| Mineral filler | 2.75 | - | - |

2.2 Methods

In this study, in order to perform the modified wheel tracking test for railway under the conditions presented above, a 305×305×50 mm slab specimen is made using cooper's roller press compactor with a target air void of 1 to 3%.

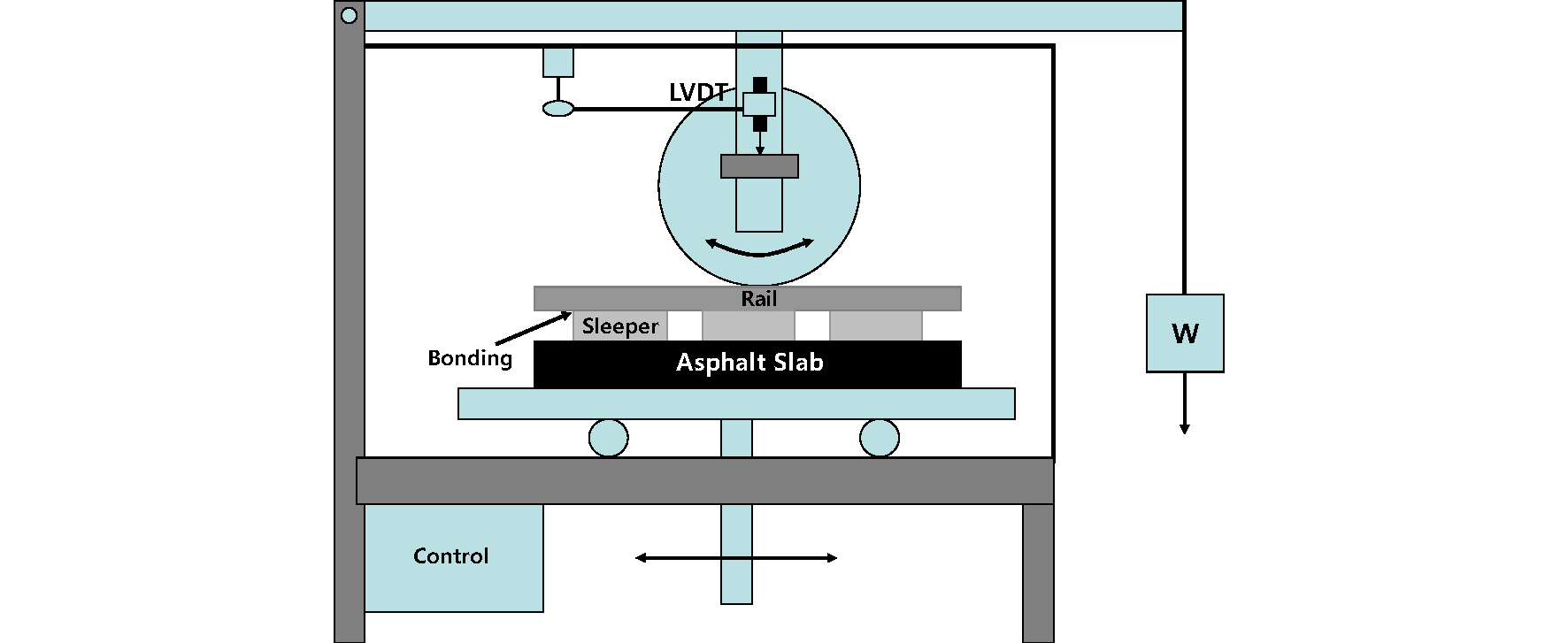

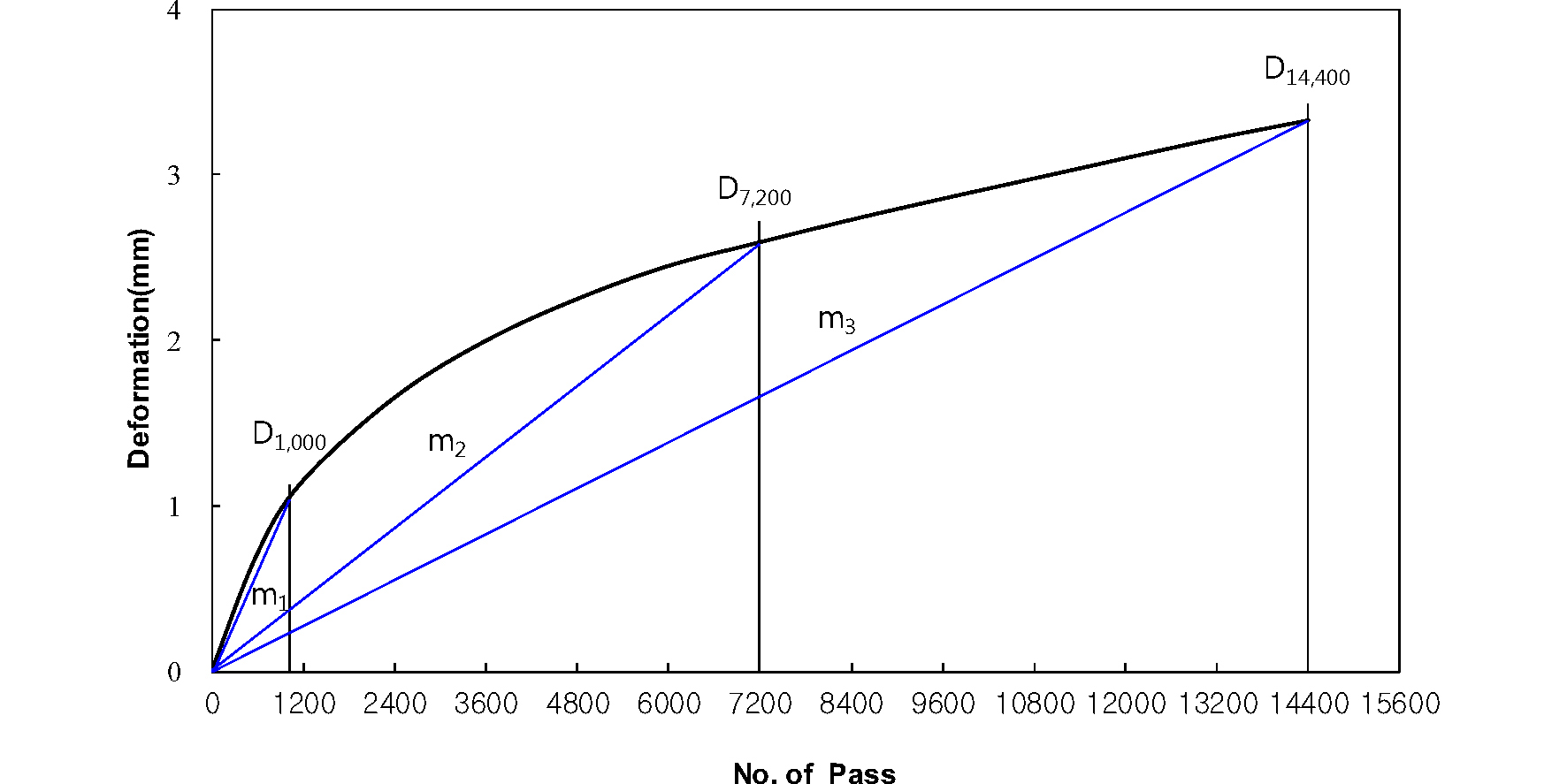

The slab specimen is used for test after curing at room temperature for 24 hours and 60℃, 65℃ for 6 hours. The rut depth was measured by wheel load with the condition of 1,296 N (132 kg) wheel load and 14,400 round for 180 mins (10,800 sec) and the raw data was acquire using linear variable differential transformer (LVDT), illustration of WT is shown in Fig. 2, Fig. 3. The frequency of data acquire is 3Hz, and the depth of rut depending on the pass is represented on the x-y axis at 60, 90, 120, 180 mins. The dynamic stability was calculated by Equation (1) from the vertical settlement graph shown in Fig. 4.

| $$DS_{rail}=m_1+m_2+m_3=\frac{1,000}{D_{1,000}}+\frac{7,200}{D_{7,200}}+\frac{14,400}{D_{14,400}}$$ | (1) |

Where, D1,000=depth (mm) at 1,000 cycle, D7,200=depth (mm) at 7,200 cycle, D14,400=final depth (mm).

3. Results and Discussions

3.1 Rut depth

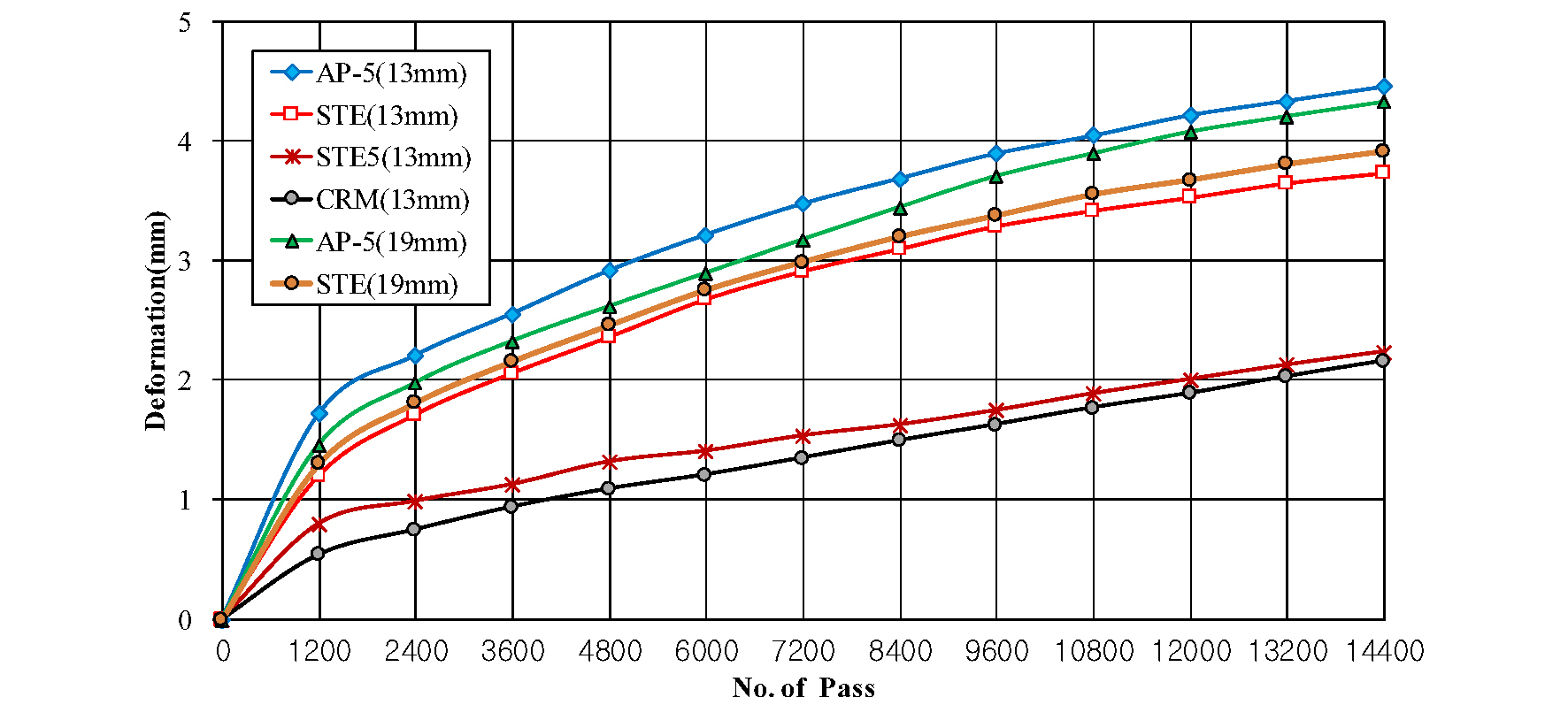

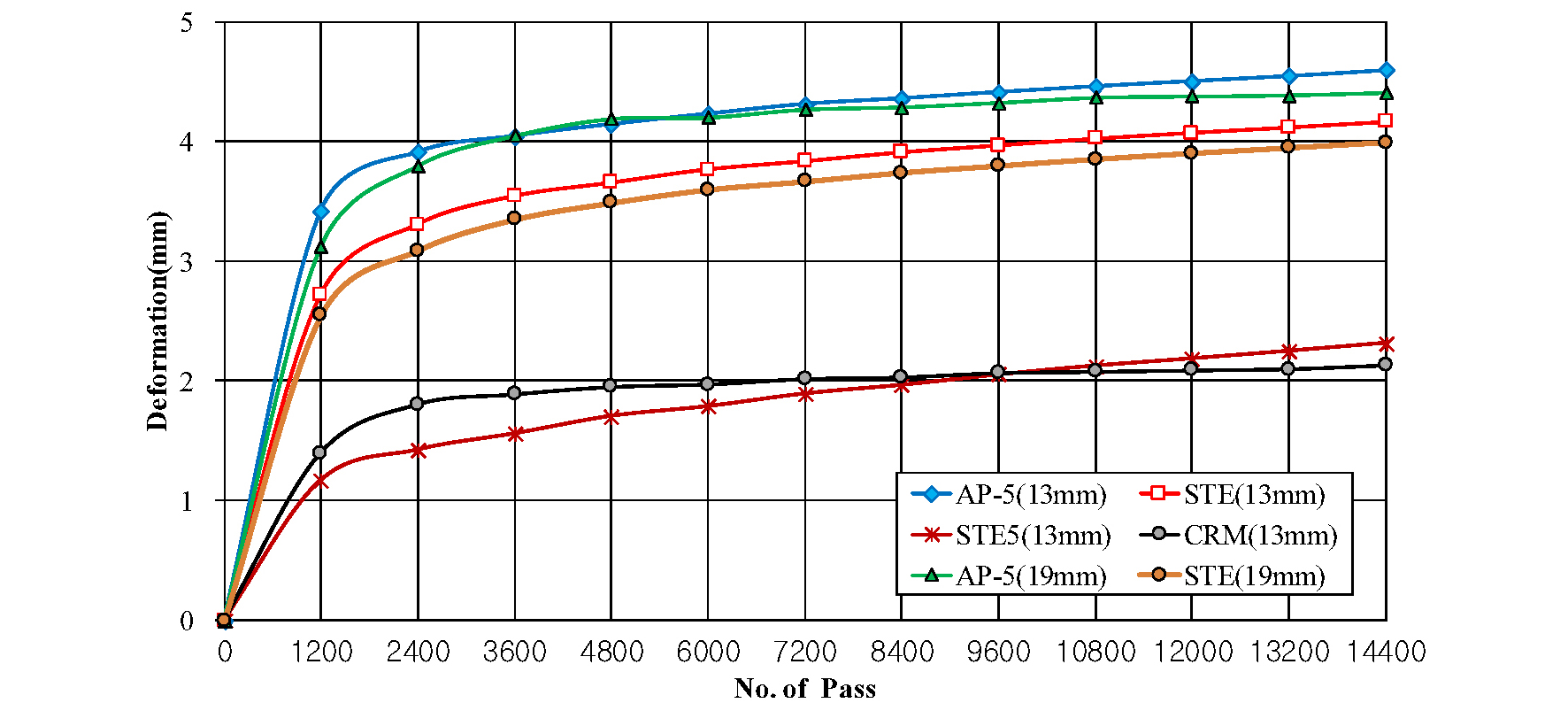

Deformation relations by the wheel tracking pass at 80 pass/min for 6 types of asphalt mixtures (4 types of 13 mm asphalt mixtures and 2 types of 19 mm asphalt mixtures) at 60℃ are shown in Fig. 5 and Fig. 6 below. From the results of 60℃ shown in Fig. 5, the rut depth rapidly increased up to 1,200 pass and then slowly increased. It was confirmed that the final rut depth between the mixture of PG64-22 and PG76-22 after wheel tracking 14,400 pass was 4.1 mm and 2.2 mm, resulting in a 1.9 mm difference. CRM and STE5, PG76-22, were 2.16 mm and 2.24 mm, respectively, which were significantly different from PG64-22 asphalt mixture. It can be seen that the asphalt mixture modified with CRM has a low depth, and there is a difference in deformation depending on the type of the mixture. Furthermore, both mixtures showed a sharp graph curve of rut depth up to 1,200 pass, and then showed the gentle slope after that. Both types (PG64-22, PG76-22) showed the similar tendency.

The results from MWTT at 65℃ shown in Fig. 6, and the final rut depth of 6 types, 4 types of PG64-22 and 2 types of PG76-22, was compared to the results at 60℃. The results of comparison, similar rut depth was obtained between the same PG grades. The initial rut depth up to 1,200 pass for six mixtures was about 2.4 mm, and the final rut depth was about 3.6 mm. The initial rut depth up to 1,200 pass, 2.4 mm, was 50% higher than 1.2 mm between 1,200 pass and 14,400 pass. In other words, in the case of the measurement at 65℃, most of the deformation occurred in the range of first 15 mins.

Depending on the type of asphalt mixture, there was a difference by the material, and as in the result at 60℃, PG76-22 had a lower depth than the PG64-22 asphalt mixture at 65℃. In addition, depending on the type of mixture, PG64-22 mixture, AP-5 (13 mm) and AP-5 (19 mm) showed the highest rut depth of 4.4 mm or higher and STE (19 mm), PG64-22, showed the lowest rut depth. The PG64-22 mixture showed a slower curve of increase in rut depth compared to PG76-22, and CRM (13 mm) had a lower rut depth than STE5 (13 mm), indicating good permanent deformation resistance.

Through the previous experiments, it was found that the tendency of large deformation during the initial 900 sec (15 mins), and to determine this, the initial deformation, the ratio of rut depth at 900 ses (15 mins) and 10,800 sec (180 mins) was compared and shown in Table 3. PD1,200/PD14,400 value with 80 pass/min showed a difference by temperature, and 60℃=0.33 and 65℃=0.65, which resulted in more initial deformation than 60℃.

Table 3. Ratio of Permanent Deformation (PD1,200/PD14,400)

PD1,200/PD14,400 value depending on maximum size of coarse aggregate in PG64-22 mixture is 13 mm=0.39, 19 mm=0.37 at 60℃, 13 mm=0.67, 19 mm=0.64 at 65℃, and there is no big difference depending on material, but there is a difference depending on temperature.

3.2 Dynamic stability

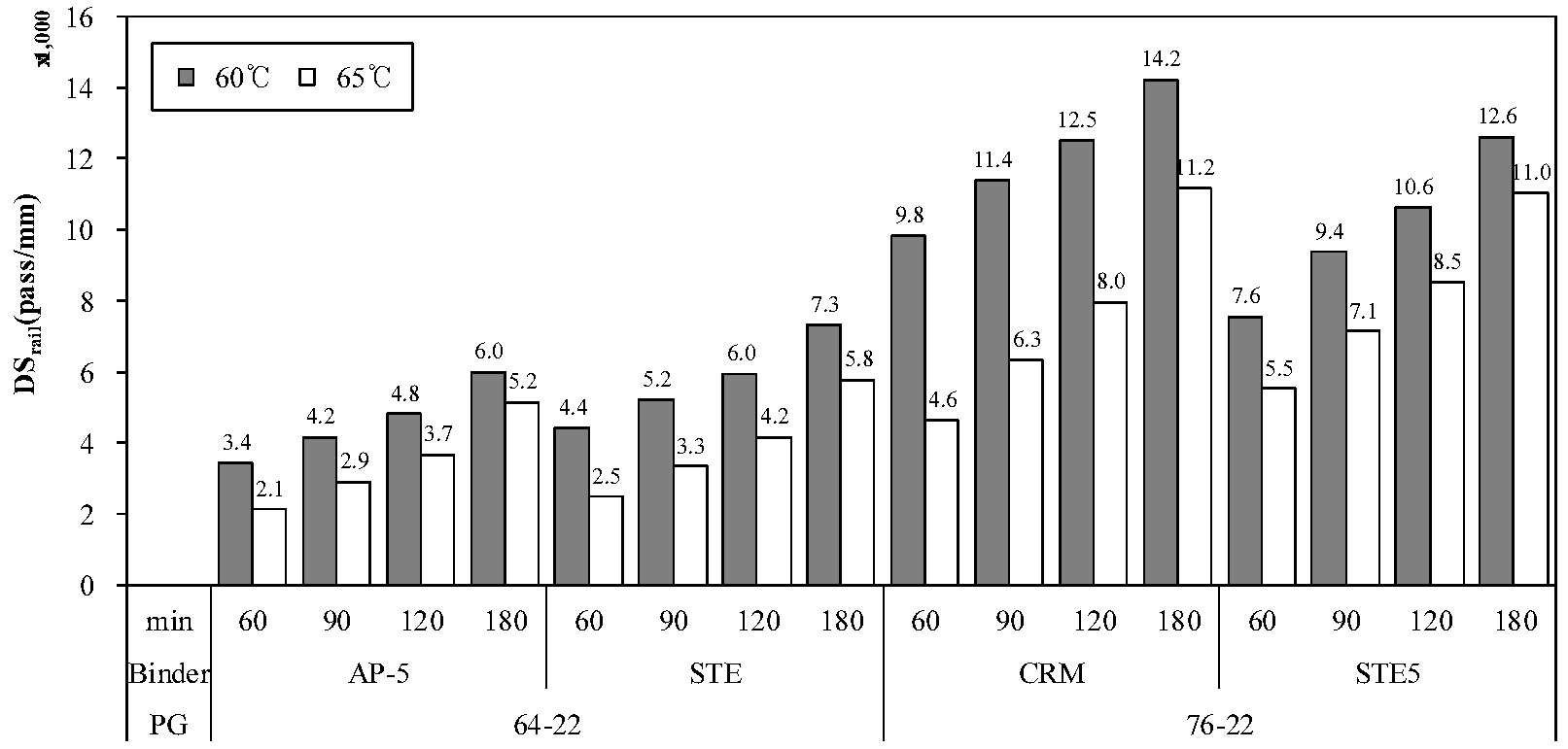

The dynamic stability of the 13 mm asphalt mixture applied to the cyclic loading test by the DSrail formula at two different temperature was compared as shown in Fig. 7. The dynamic stability of 60℃ was higher than 65℃, but the tendency to increase was similar.

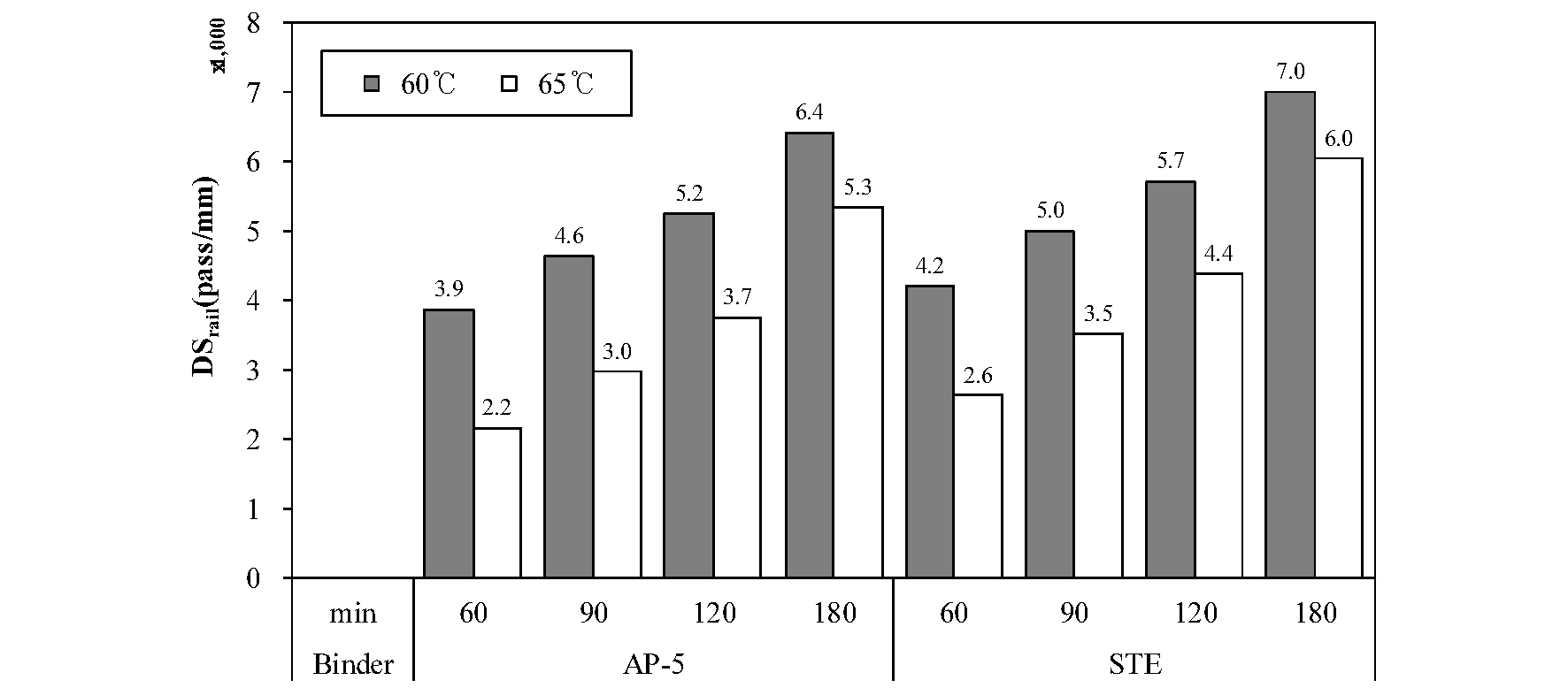

In addition, the almost same stability and tendency were observed at the two temperatures in the CRM and STE5 mixtures, which are PG76-22, and the same tendency was observed in the PG64-22 mixture. The 19 mm asphalt mixture showed a characteristic of at 60℃ higher than at 65℃ for DSrail as shown in Fig. 8 and showed a tendency to increase at regular intervals. Furthermore, in terms of difference depending on temperature for DSrail, AP-5 ranged from 1.1 to 1.7 pass/mm and STE showed 1 to 1.6 pass/mm.

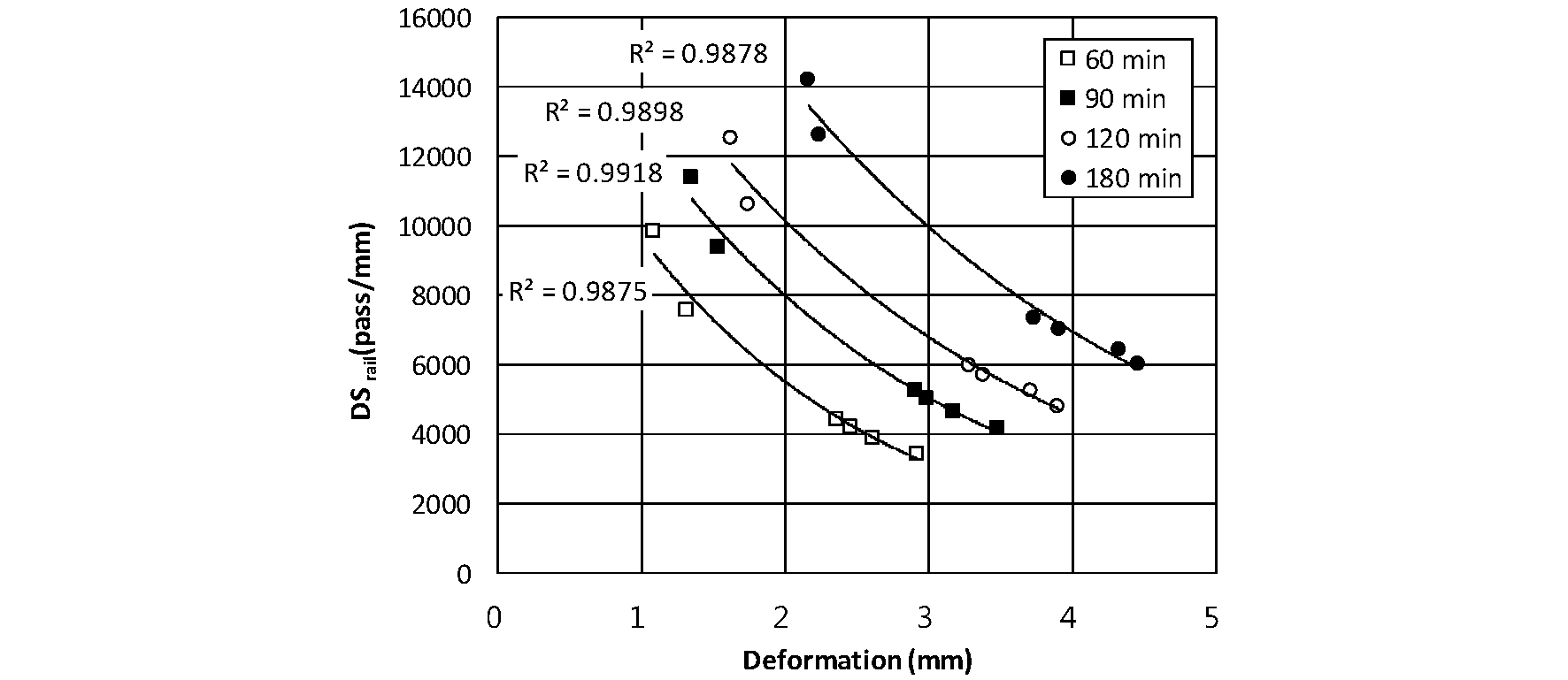

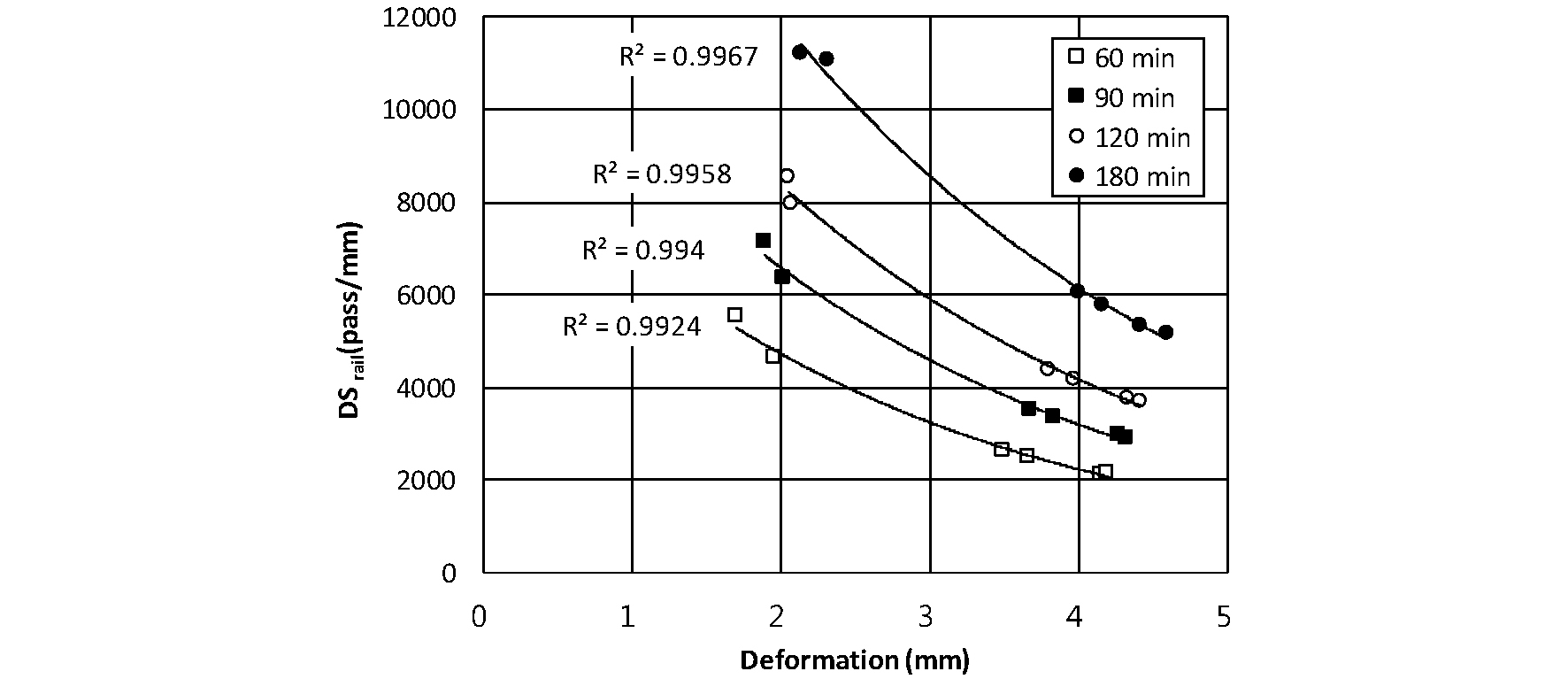

The correlation between deformation and DSrail at 60℃ depending on wheel tracking time at 80 pass/ min of MWTT is shown in Fig. 9. Based on the results, DSrail did not show a constant tendency with wheel tracking time, but it had a value of R2>0.98 for 4 different time (60 min, 90 min, 120 min, 180 min). among them, at 90 min R2 is the highest as 0.99. It has been found that DSrail calculation method at 90 min is advantageous for evaluating the asphalt mixture. The correlation between deformation and DSrail at 65℃ depending on wheel tracking time at 80 pass/min of MWTT is shown in Fig. 10. it had a value of R2>0.98 for 4 different wheel tracking time (60 min, 90 min, 120 min, 180 min). Dynamic stability calculated from the results of MWTT was high at both 60℃ and 65, especially at 65℃.

4. Conclusions

In this study, the result of evaluation of the permanent deformation resistance of the asphalt mixture considering the railroad conditions were obtained. When the temperature was 65℃, the initial rut depth was larger than the temperature of 60℃. In other words, it was confirmed through the lab test results that the increase of temperature is the main factor to cause the initial permanent deformation. In the MWTT test with rails and sleepers, all of the five asphalt mixtures showed a significant change in the rut depth depending on PG grade. Wheel tracking time in MWTT seems to be suitable between 60 and 90 mins in consideration of the deformation speed and the deformation variation range. Considering the various mixtures, the longest time of 90 min seems to be effective for the relative evaluation between specimens.